Technical Data

32

Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)

42/14-36 EN

Type

FMT400-VTS (Sensyflow VT-S)

FMT400-VTCS (Sensyflow VT-CS)

Operating conditions

Recommended

inlet and outlet runs

acc. to DIN EN ISO 5167-1

min. inlet 15

×

D, outlet 5

×

D

Environmental conditions

Ambient temperature

Connection head

-25...+70 °C

Storage temperature

-25...+85 °C

Process conditions

Operating temperature medium

(transducer)

Ceramic sensor: -25...+300°C

Metal sensor: -25...+250°C

-25...+150 °C

Operating pressure (max.)

40

×

10

5

Pa (40 bar)

16

×

10

5

Pa (16 bar) pipe fitting S

(for DN 80: 10

×

10

5

Pa (10 bar))

10

×

10

5

Pa (10 bar) FG flange

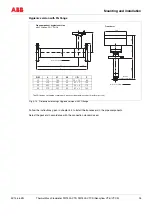

Pressure loss

(logarithmic diagram)

< 1.0 kPa (10 mbar), typical value 0.1 kPa (1 mbar)

Mechanical construction

Design/dimensions/weight

dependent on nominal size

dependent on nominal size

Material (standard)

1.4571, Ceramics

stainless steel e.g. 1.4301

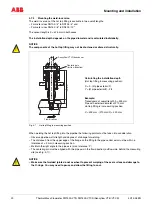

Process connection (standard)

Flange acc. to EN 1092-1 form B1, PN 40 or

ANSI B 16.5 150/300 lbs

Pipe fitting S acc. to DIN 11851

or FG flange

Components

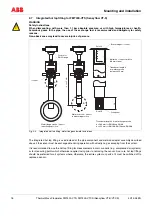

– VTS transducer

– VT pipe component design 1 or 2

or weld-on adapter

VTCS transducer

VTC pipe component

Standard nominal pipe sizes

Pipe component design 1: Wafer flange

DN 40, 50, 80, 100, 150, 200 –

ANSI 1½“, 2“, 3“, 4“, 6“, 8“

Pipe component design 2: measuring section

DN 25, 40, 50 – ANSI 1“, 1½“, 2“

Weld-on adapter for square ducts

or pipe sizes

≥

DN 150

Pipe component hygienic version: measuring section

DN 25, 40, 50, 80

Type of protection

IP 65

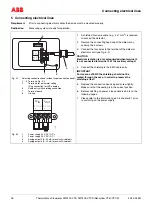

Auxilary energy

Electrical power supply

Voltage

Power consumption

Current drain

24 V DC

±

25 %; 24 V AC

±

25 %, 48...62 Hz

< 15 W

< 600 mA, slow-blow fuse of at least 2 A recommended

Cable entry

M20 x 1.5

10

50

100

500

1000

5000 10000

10

5

0,5

0,1

1

DN 50

DN 80

DN 100

DN 150

Z-18927

DN 25

Pressure drop (mbar)

Mass flow rate (kg/h)