Mounting and installation

14

Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)

42/14-36 EN

4.4

Installation

CAUTION

Safety instructions

When dismounting, with more than 1.1 bar absolute pressure, or with high temperatures or health-

hazardous gases in the pipe, the use of the exchange tool is recommended and obligatory for safety rea-

sons

(see chapter 4.7).

Non-observance may lead to severe injuries of persons.

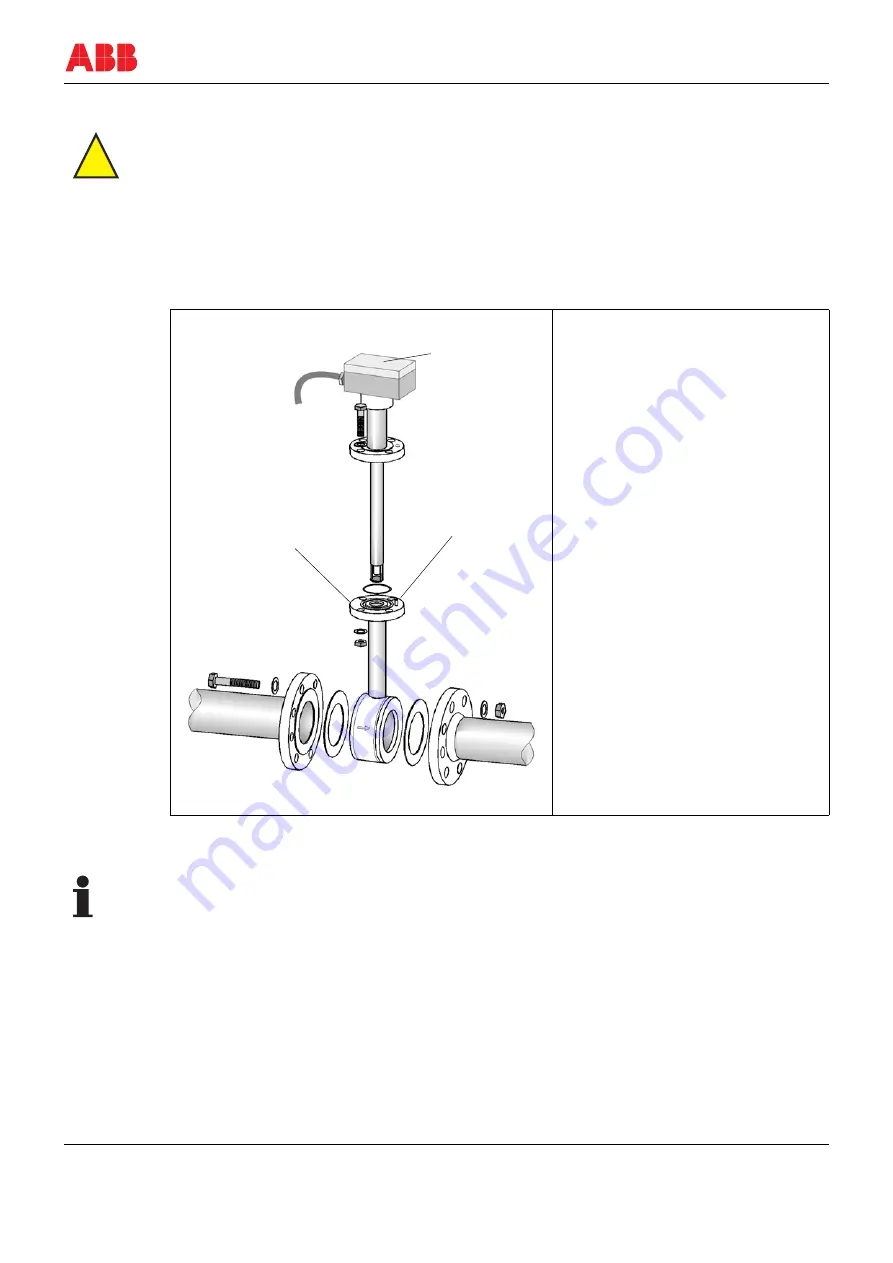

The installation is described using the example of a pipe component of type 1 in intermediate flange version. The

description analogously also applies to a type 2 pipe component and the weld-on adapters.

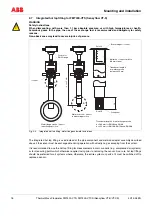

Fig. 4-1

Schematic illustration of a pipe component 1 with intermediate flange

IMPORTANT

In the case of the type 1 pipe component (intermediate flange version) with ball valve and a nominal width

DN 200 / ANSI 8", transducers with a length of 425 mm must be used.

!

(1) Centering pin

1.

The flow direction must agree with the

direction shown by the arrow on the pipe

component.

2.

The opening diameter of the sealings

used may not be changed and should on

completion of the component installation

guarantee that the detecting element and

the pipe are absolutely leakproof.

3.

The centering pin on the pipe component

(Fig. 4-1) or weld-on adapter must be lo-

cated downstream side (behind the mea-

suring point).

4.

Check the supplied O-ring (55 x 3 mm)

between the transducer and the pipe

component / weld-on adapter for signs

of damage prior to installation. Insert the

O-ring exactly into the groove of the

DN 25 flange.

5.

All flange screws must be installed

properly.

(1)

Pipe component 1 in

wafer flange design

DN 40 to DN 200

ANSI 1½“ to 8“

Transducer

FMT400-VTS