Assembly Instructions

Pressurising the poles

1HSB435410-2 enrev1

31

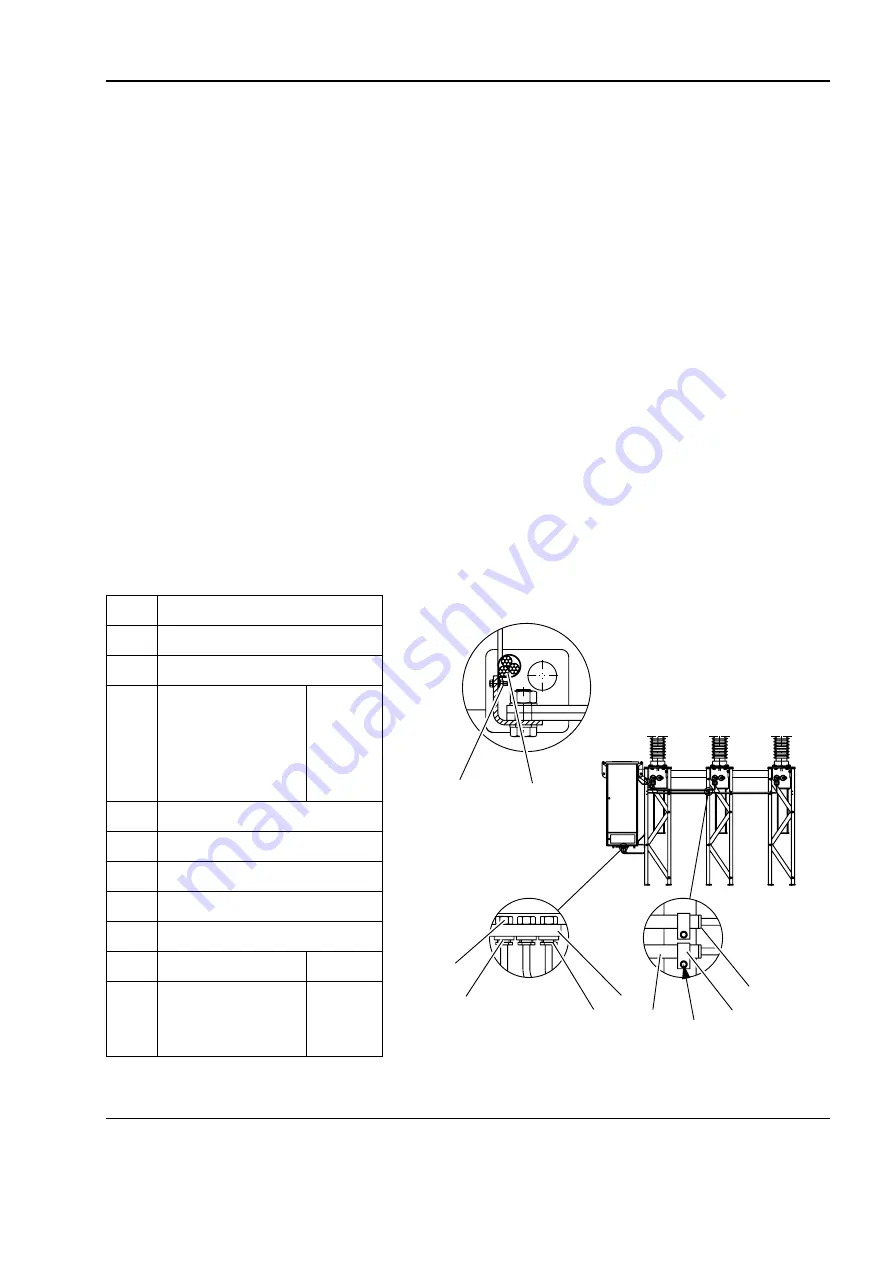

6.3 Gas monitoring system

•

Secure the protective tube (1) to the frame using pipe clips (2) and bolts, nuts

and washers (3).

•

Fit a bushing (4) on each cable to be pulled through the protective tube and pull

through the cable.

•

Also fit bushings to the other end of the protective tube.

•

Connect the cable to the density monitor’s terminal blocks.

•

Drill three 23 mm diameter holes in the flange (5) on the bottom of the

operating mechanism and fit cable glands (6) with sealing washers (7) and nuts

(8) in the holes.

•

Insert the cable through the cable glands in the operating mechanism and

connect them to the terminal blocks as stated on the applicable operating

mechanism’s circuit diagram

•

Tighten the cable glands (6) to secure the cables.

•

Secure the cable to the frame’s leg using pipe clips (9) and nuts, bolts and

washers (10).

N.B. The cable ends for the density monitor should be as long as necessary so that

the density monitor can be disconnected from the non-return valve without

the need of disconnecting the cable.

Figure 6-3. Gas monitoring

Item

1

Protective tube

2

Pipe clips

3

Bolts M6x25

Nuts M6

Washers

6.4x15x1.5

Retaining washers

5 pcs.

5 pcs.

10 pcs.

5 pcs.

4

Bushing

5

Flange

6

Cable gland

7

Sealing washer

8

Nut

9

Pipe clips

4 pcs.

10

Bolts M5x20

Nuts M5

Washers 5.3x10x1

4 pcs.

4 pcs.

8 pcs.

5

6

7

9

8

10

B10078

1

2

3

4

Summary of Contents for SF6 LTB 245E1 BLG 1002A

Page 1: ...Product Manual 1HSB435416 2 en Rev 1 LTB 245E1 BLG 1002A 3 pole operation ...

Page 92: ...ABB Switchgear SF6 Circuit Breaker Circuit breakers HPL and LTB 1HSB445409 1 en0 Lubricants ...

Page 198: ......

Page 199: ......

Page 209: ......

Page 210: ......