Advanced Videographic Recorder

SM2000

Appendix B – Modbus Guide

110

IM/SM2000

Issue 11

Appendix B – Modbus Guide

B.1 Introduction

This instrument is fitted with a Modbus/RS485 serial

communications link as standard.

The instrument can be configured to act as either a Remote

Terminal Unit (RTU) slave when communicating with a master

(host) system, or as a Modbus master device, enabling it to

collect data from RTU slaves into its 24 Comms Analog and 24

Comms Digital Channels.

B.2 Setting Up

To set up the instrument on a Modbus network:

1. Connect the instrument to a Modbus link – see Section

2. Set the RS485 configuration parameters – see Section

3. Add the instrument to the link configuration on the host

system – refer to information supplied with the host

system.

B.3 Modbus Commands Supported

The following Modbus commands are supported:

B.4 Modbus Exception Responses

If the instrument detects one of the errors listed in Table A2.1

while receiving a message from the host system, it replies with a

response message consisting of the instrument's Modbus

address, the function code, the error code and error check

fields.

B.5 Operating Mode Modbus Coils

Tables A2.2 to A2.14 detail the contents of each Modbus coil.

Each coil is assigned a register that can have one of two values:

0000 and 0001.

01

Read Coil Status

– reads the on/off status of 16

consecutive digital states, starting at a specified address.

The instrument returns zeros for points which do not contain

defined data

03

Read Holding Registers

– reads 8 consecutive analog

values, starting from a specified address. The instrument

returns zeros for registers which do not contain defined

data.

05

Force Single Coil

– sets the value of a single coil (digital

signal) at the specified address. The data value must be

FF00

Hex

to set the signal ON and zero to turn it OFF. The

instrument returns an exception response if the register is

not currently writable.

06

Preset Single Register

– sets the value of a single register

(analog value) at the specified address. The instrument

returns an exception response if the register is not currently

writable. Limits defined in configuration are applied to the

value before storage.

08

Loopback Diagnostic Test

– used to test the integrity of

Modbus transmissions. The instrument returns the message

received.

15

Force Multiple Coils

– the instrument carries out updates

that are valid and returns an exception response if any of the

coils are not currently writable.

16

Preset Multiple Registers

– the instrument carries out

updates that are valid and generates an exception response

if any of the registers are not currently writable.

Note.

Negative numbers are represented in '2's

complement' format, e.g 1000 = 03E8 (Hex), -1000 =

FC18 (Hex)

The instrument cannot accept a new message until

the current message has been processed and a reply

sent to the master (maximum response time 50ms).

The instrument monitors the elapsed time between

receipt of characters from the host. If the elapsed time

between two characters is 3.5 character times, the

slave assumes the second character received is the

start of a new message.

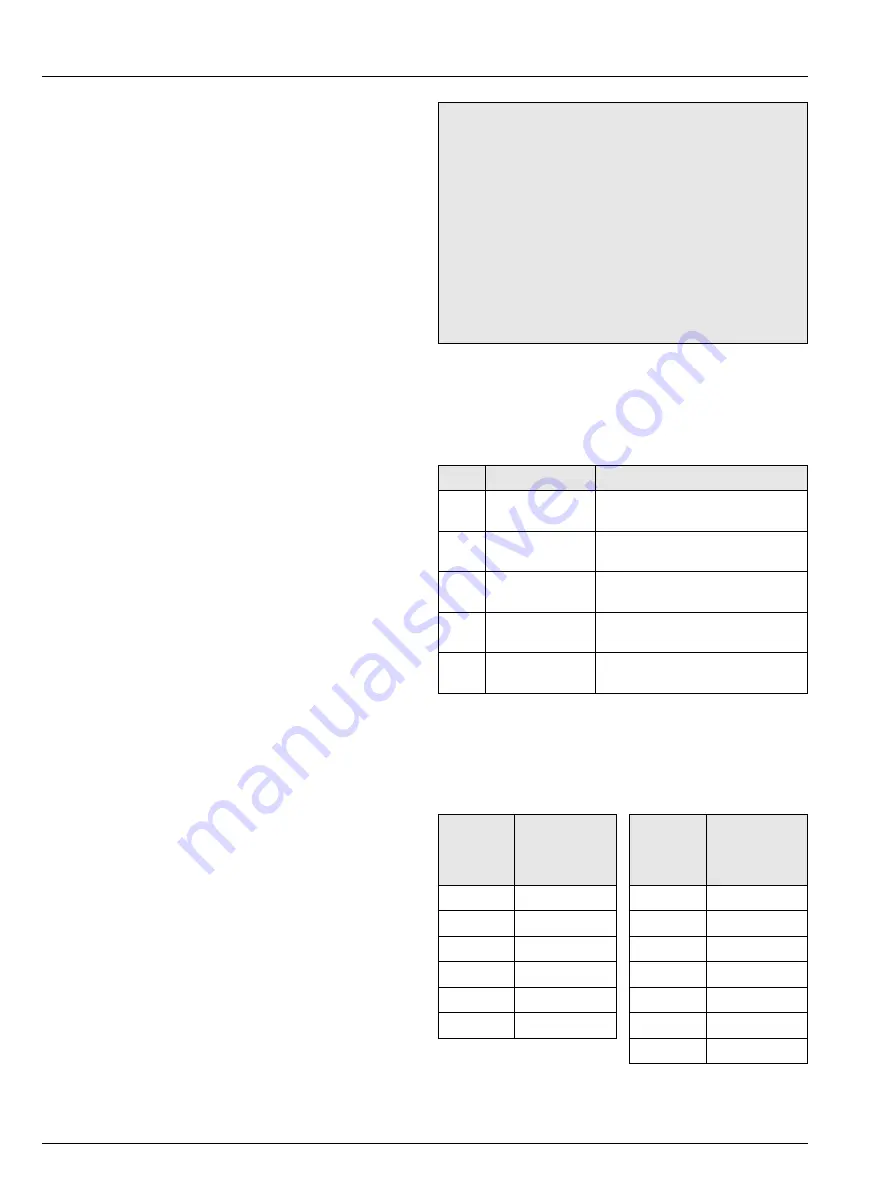

Code

Name

Definition

01

Illegal Function

The message function received is not

an allowable action

02

Illegal Data

Address

The address reference in the data field

is not an allowable address

03

Illegal Data Value

The value referenced in the data field

is not allowable in the addressed slave

07

Negative

Acknowledgment

Received message error

08

Memory Parity

Error

Parity check indicates an error in one

or more of the characters received

Table B.1 Modbus Exception Responses

Analog

Input

Modbus Coil

(Read Only)

0 = Input OK

1 = Input failed

Analog

Input

Modbus Coil

(Read Only)

0 = Input OK

1 = Input failed

A1

0001

B1

0007

A2

0002

B2

0008

A3

0003

B3

0009

A4

0004

B4

0010

A5

0005

B5

0011

A6

0006

B6

0012

Reserved

0013 to 0050

Table B.2 Analog Input Fail States