79

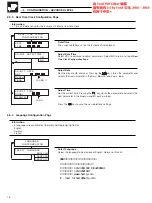

TOTALISER

CONFIGURATION

TOTALISER TO

CONFIGURE

TOTALISER SOURCE

Analog Input

Maths Result M

NONE

NONE

TOTALISER COUNT

DIRECTION UP

DOWN

TOTALISER UNITS

TOTALISER TAG

S

RESET YES

NO

TOTALISER COUNT

F.S. PUL/SEC

TOTALISER COUNT

DECPT PUL/SEC

TOTALISER COUNT

ZERO PUL/SEC

TOTALISER COUNT

CUT OFF %

TOTALISER DECPT

T UNITS

6789:;<=>?@ABCDEF

6789:;<=>?@ABCDEF

T TAG

NONE

6

CONFIGURATION – ADVANCED LEVEL…

6.4.2

Totalizer Configuration Page

This page is used to configure the totalizers T1 to T6.

Totalizer to Configure

Select the totalizer to configure (T1 to T6).

On entry the default is

NONE

.

Totalizer Source

An input source is assigned to the totalizer selected above. Select the source

required from analog inputs A1 to A6, B1 to B6 (depending on the options fitted

– see Section 4.2) or math functions M1 to M4.

Select

NONE

to set the totalizer off.

Totalizer Count Direction

Select either an incremental (

UP

) or decremental (

DOWN

) counter.

Totalizer Units

Units of up to six characters can be set on

the upper display – see Front Fold-out.

Totalizer Tag

A totalizer name of up to eight characters

can be set on the upper display – see Front

Fold-out.

Secure Total

The secure total for the totalizer selected above is displayed. This value is

independent of the displayed flow total and can comprise up to ten digits as set

in the

Totalizer Decimal Point

parameter – see below.

Select

YES

and press enter to reset the secure total. The figure displayed

depends on the type of counter selected (

UP

or

DOWN

)

Totalizer Count Full Scale

Set the required count (pulses/second) corresponding to the full scale input. This is

programmable from 0.00 to 10.00 in 0.01 increments, or from 0.000 to 1.000 in

0.001 increments depending on the decimal point setting in the next parameter.

Totalizer Count Decimal Point

Set the required position of the decimal point for the count full scale set above.

This can be set to give increments of 0.01 or 0.001.

Totalizer Count Zero

Set the required count rate corresponding to zero input as for

Totalizer Count Full

Scale

above.

Totalizer Count Cut Off

Set the lowest flow value (as a percentage of maximum flow rate) at which the

totalizer is to stop counting. This is adjustable from 0.0 to 100.0% in 0.1%

increments.

Totalizer Decimal Point

Set the decimal point for the displayed flow total and secure total. This is

selectable between .00000000 and 00000000., with multiplication factors of x10

and x100 available, i.e. 000000000 and 0000000000.

Continued on next page.