1

WARNING: Because of the possible danger to person(s)

or property from accidents which may result from the

improper use of products, it is important that correct

procedures be followed. Products must be used in

accordance with the engineering information specified

in the catalog. Proper installation, maintenance and

operation procedures must be observed. The instructions

in the instruction manuals must be followed. Inspections

should be made as necessary to assure safe operation

under prevailing conditions. Proper guards and other

suitable safety devices or procedures as may be desirable

or as may be specified in safety codes should be provided,

and are neither provided by ABB nor are the responsibility

of ABB. This unit and its associated equipment must be

installed, adjusted and maintained by qualified personnel

who are familiar with the construction and operation of

all equipment in the system and the potential hazards

involved. When risk to persons or property may be

involved, a holding device must be an integral part of the

driven equipment beyond the speed reducer output shaft.

Instruction Manual

Dodge

®

Torque-Arm

™

II Speed Reducers

Ratios 5, 9, 15, 25, and 40:1

TA0107L

TA3203H

TA6307H

TA9415H

TA1107H

TA4207H

TA7315H

TA10507H

TA2115H

TA5215H

TA8407H

TA12608H

These instructions must be read thoroughly before installation or operation. This instruction manual was accurate at the time of

printing. Please see

baldor.com

for updated instruction manuals.

Note! The manufacturer of these products, Baldor Electric Company, became ABB Motors and Mechanical Inc. on

March 1, 2018. Nameplates, Declaration of Conformity and other collateral material may contain the company name of

Baldor Electric Company and the brand names of Baldor-Dodge and Baldor-Reliance until such time as all materials have

been updated to reflect our new corporate identity.

WARNING: To ensure the drive is not unexpectedly

started, turn off and lock-out or tag power source before

proceeding. Failure to observe these precautions could

result in bodily injury.

WARNING: All products over 25 kg (55 lbs) are noted on the

shipping package. Proper lifting practices are required for

these products.

WARNING: Torque-Arm II product exceeding 13.5 kg (30

lbs) should be lifted using lift-assist equipment rated for

the weight of the product. Weight values for all Torque-Arm

II products are listing in the Gearing Engineering Catalog.

Lifting brackets provided on the Torque-Arm II should be

used when connecting to the lift-assist equipment.

WARNING: Depending on operating conditions, sound

levels for Torque-Arm II products may exceed 70 dB.

Protective measures such as hearing protection may be

needed when in close proximity to a Torque-Arm II.

INSTALLATION

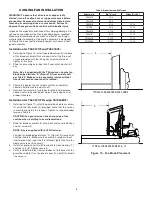

1.

Use lifting bracket to lift reducer.

2.

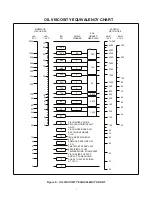

Determine the running positions of the reducer. (See

Figure 1). Note that the reducer is supplied with 6

plugs; 4 around the sides for horizontal installations

and 1 on each face for vertical installations. These

plugs must be arranged relative to the running

positions as follows:

Horizontal Installations

–Install the magnetic drain

plug in the hole closest to the bottom of the reducer.

Throw away the tape that covers the filter/ventilation plug

in shipment and install plug in topmost hole. Of the 2

remaining plugs on the sides of the reducer, the lowest

one is the minimum oil level plug.

Vertical Installations

–Install the filter/ventilation plug in

the hole provided in the upper face of the reducer housing

as installed. If space is restricted on the upper face, install

the vent in the highest hole on the side of the reducer per

Figure 1. Install a plug in the hole in the bottom face of

the reducer. Do not use this hole for the magnetic drain

plug. Of the remaining holes on the sides of the reducer,

use the plug in the upper housing half for the minimum oil

level plug.

Summary of Contents for TA0107L

Page 31: ...31 ...