10

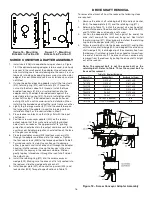

SPACER (IF APPLICABLE)

BACKSTOP SHAFT

COVER GASKET

REDUCER WITH

BACKSTOP INSTALLED

REDUCER WITHOUT

BACKSTOP INSTALLED

ARROW ON HUB OF INSTALLED

BACKSTOP MUST MATCH

DIRECTION OF DESIRED

SHAFT ROTATION

RETAINING

RING

BACKSTOP

FASTENERS

BACKSTOP

KEY

OUTER RACE

INNER RACE

BACKSTOP

SHAFT COVER

Figure 12 - Backstop Assembly

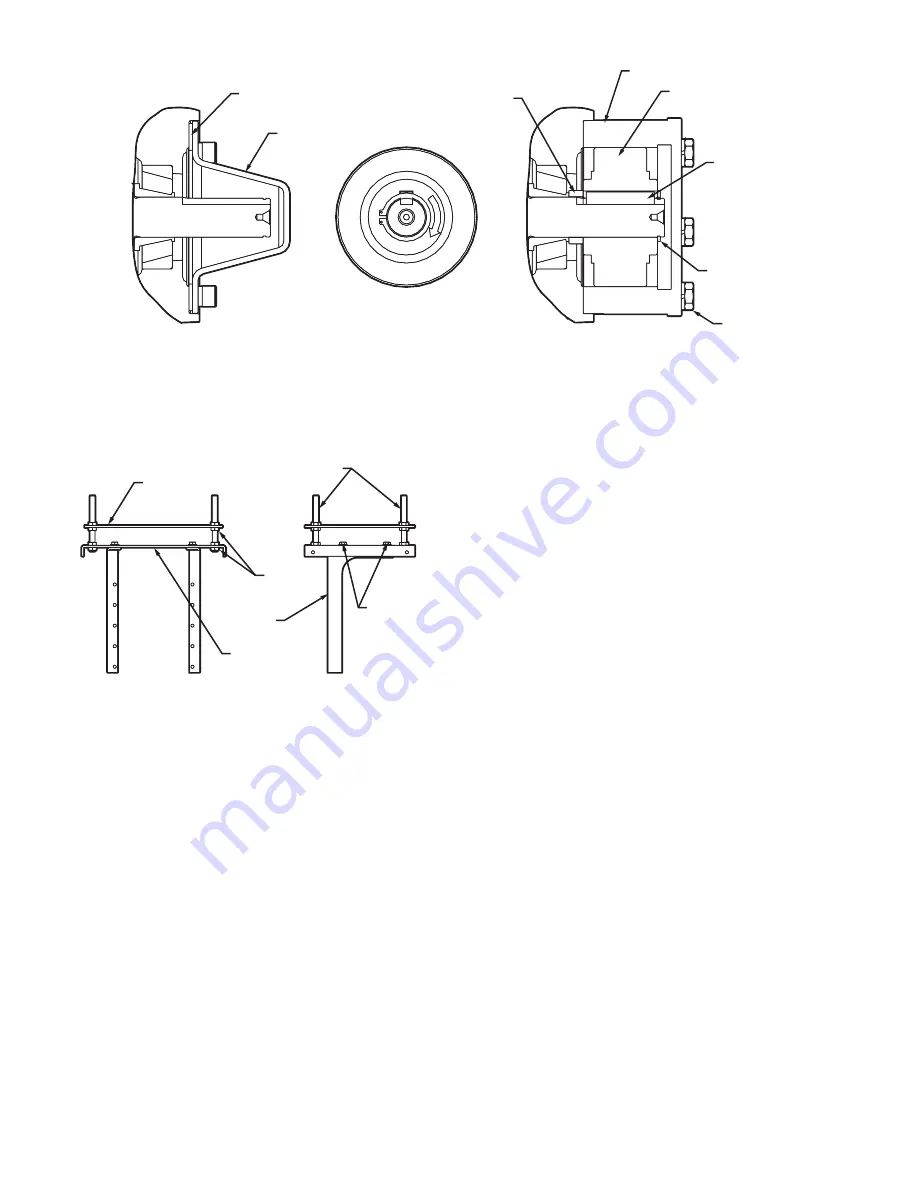

MOTOR MOUNTS

Motor Mount Assembly:

JAM

NUTS

TOP PLATE

ADJUSTING

STUDS

BOTTOM

PLATE

BOLTS

UPRIGHTS

BOTTOM

PLATE

Figure 13 – Motor Mount Components

Refer to Figure 12 for descriptions of component parts. Using

the hardware provided, assemble uprights (the angled parts

to which the reducer is fastened) to the u-shaped, rectangular

bottom plate. Notice that there are eight slots cut into the plate.

If the reducer is to be mounted in Positions A or C, as illustrated

in Figure 8, assemble the uprights in the outermost slots. If

the reducer is to be mounted in Positions B or D, assemble

the uprights in the innermost slots. The bottom plate may be

mounted with the vertical flanges up or down (as shown in

Figure 11). Snug bolts only, do not torque bolts at this time.

Fasten long threaded studs to the four corners of bottom plate

using jam nuts, one on each side of the plate. Securely tighten

these nuts, as they will not require any further adjustment. Add

ne additional jam nut to each stud and thread approximately

to the middle of the stud. Assemble top motor plate (the flat

rectangular plate with many holes) on top of the jam nuts.

Assemble the remaining jam nuts on studs to secure top motor

plate. Do not fully tighten these nuts yet.

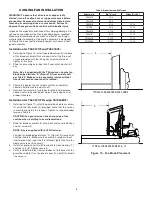

The motor mount may be installed in any of the four positions

(A, B, C or D) and in any of the mounting levels (M1, M2, M3 or

M4) shown in Figure 12. Note that the motor mount uprights

attach to the input side of the reducer when mounted in either

the “B” or “D” positions.

Motor Mount Installation:

WARNING: To ensure that drive is not unexpectedly

started, turn off and lock out or tag power source before

proceeding. Remove all external loads from drive before

removing or servicing drive or accessories. Failure to

observe these precautions could result in bodily injury.

Remove four or six (as required) housing bolts from the reducer.

Place the motor mount in position and reinstall the bolts

through the motor mount uprights and reducer housing. Where

reducer is shaft mounted in positions A or C, the torque-arm

adapter plate must be mounted between the reducer housing

and the motor mount upright. Tighten bolts to the torque

specified in Table 12.

Mount the motor onto the top plate and bolt securely. Install the

motor sheave and reducer sheave as close to the motor and

reducer housings as practical. Loosen the bottom plate bolts

and slide the motor and mounting plate to accurately align the

motor and reducer sheave. Securely tighten the bottom plate

bolts. Install the required number of V-belts and tension belts

by alternately adjusting the jam nuts on the four adjusting studs

provided on the motor mount. Check all bolts to see that they

are securely tightened. Verify that the V-belt drive is properly

aligned before operating the reducer.

Summary of Contents for TA0107L

Page 31: ...31 ...