1YSA160003-EN - Rev. 5

5 / 19

Section C: Operation of the AutoLink

C.1.

General

The AutoLink Electronic Sectionalizer is a protection device that operates at a permanent fault in the distribution line. It must be

used together with an upstream recloser or circuit breaker with reclosure capability. Please take note that the AutoLink is not a fuse tripping

device, therefore it cannot be used as a protection device by itself.

The main function of the AutoLink is to discriminate between permanent and transient faults in the distribution line, making it

possible for the upstream recloser or substation breaker to clear transient faults without permanent interruption to the customers.

The AutoLink is not a fuse tripping device, it will operate to isolate a permanent fault on no load condition. The AutoLink fits into

a standard fuse cutout and it directly replaces an existing fuse base. When it operates the AutoLink drops open like a fuse.

The AutoLink Electronic Sectionalizer is designed ONLY to protect electrical

equipment and NOT for saving people from accidents or electrocution when

contacting energized circuits.

C.2.

Operating Under Fault Conditions

C.2.1.

Operating Under Temporary Fault Conditions

In distribution overhead lines 80-90% of the faults are temporary, and are cleared by an upstream recloser or breaker.

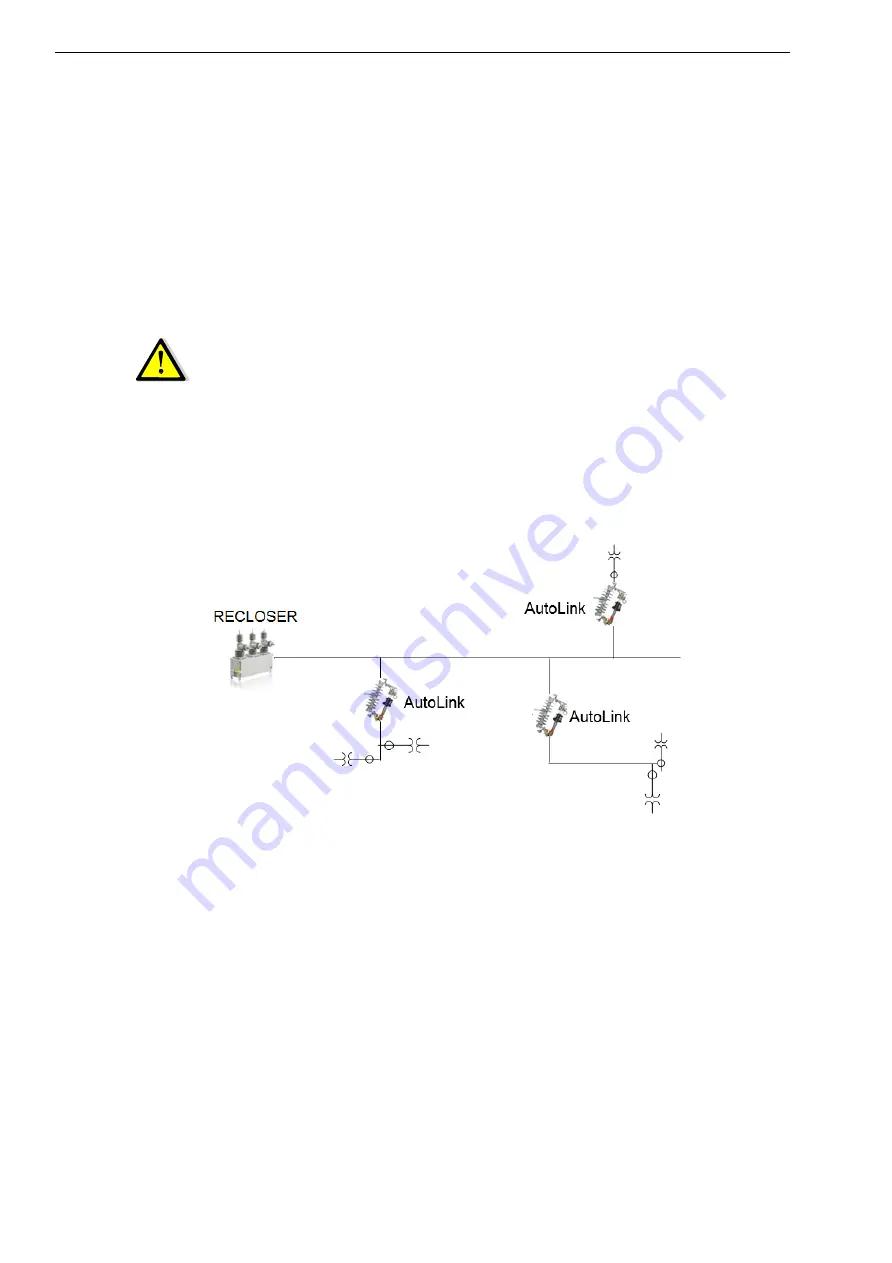

Figure 1.

The AutoLink is in monitor mode under normal load conditions. When a fault is present the AutoLink senses a current above a

programmed pickup threshold (Ia AutoLink) and becomes active. It waits an opening of the upstream recloser or breaker. At the occurrence

of zero current, the sectionalizer registers the first count. If the upstream recloser or breaker closes and no further fault is detected (temporary

fault condition) within the memory resetting time, the AutoLink will time out, reset its counter and return to the monitor mode.