L3692

Tmax T8

15/39

Doc N°

Mod.

Apparatus

Scale

Page N°

1SDH000682R0002

L3885

L5757

8.3.7. Protection

releases

- -Power the protection release with a PR030/B battery unit.

- Make sure that the protection release functions correctly: release test with the “Trip Test” (PR232, PR331, PR332) and “Autotest”

(PR332)

- With release PR332, make sure that the front leds or display do not indicate the presence of alarms.

- With release PR232 and PR331, make sure that the front leds do not indicate the presence of alarms.

- Make sure that the cables are correctly connected to the release modules and to the release itself (if applicable).

- Check the percentage of wear on the circuit-breaker contacts in PR332.

- Remove the PR030/B battery unit from the relay upon termination.

8.3.8.1 Test with SD Testbus2 (optional)

- Connect unit BT030 or BT030-USB to the relay that needs to be tested.

- Run the SD.TestBus2 program in a PC equipped with Bluetooth or Flash Drive connection, depending on the version of the

BT030 used.

- Once the connection between the relay and PC has been established, make sure that there are no alarm signals from the relay.

If this is the case, consult the ‘error messages’ and/or ‘troubleshooting’ sections of this manual.

- In normal operating conditions, proceed with the trip test and autotest (depending on the type of relay). For future check-outs,

you are advised to enter the current information in the area called User Data and/or Tag Name. These data will remain stored

in the relay itself.

- Remove the BT030 or BT030-USB fl ash drive from the relay.

8.4.8.2 Test with EKIP Connect (optional)

- Connect unit T&P unit to the relay that needs to be tested.

- Run the Ekip Connect program in a PC with fl ash drive connection.

- Once the connection between the relay and PC has been established, make sure that there are no alarm signals from the relay.

If this is the case, consult the ‘error messages’ and/or ‘troubleshooting’ sections of this manual.

- In normal operating conditions, proceed with the trip test and autotest (depending on the type of relay). For future check-outs, you are advised

to enter the current information in the area called User Data and/or Tag Name. These data will remain stored in the relay itself.

- Remove the T&P cable from the relay.

1,1 Nm

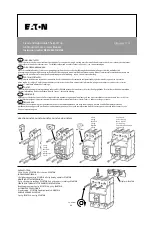

Fig. 23

8.3.9. Maintenance operations; fi nal inspections

- Fit all the parts back in place and re-connect the auxiliary power supply if necessary.

- Re-assemble the escutcheon plate as shown in fi gure 23.

- Using the different auxiliaries in succession, perform the operations 10 times:

- Opening (in both the local and remote modes, if applicable)

- Closing (in both the local and remote modes, if applicable)

- Release by means of the trip test via relay

- Check the operations in accordance with the following sequence:

- Open - Springs unloaded

- Open - Springs loaded

- Closed - Springs unloaded

- Closed - Springs loaded

- Make sure that the accessories (if installed) function correctly

- Make sure that the gearmotor (if installed) functions correctly

- Make sure that the undervoltage release functions correctly (if installed)

- Make sure that the shunt opening release functions correctly (if installed)

- Make sure that the shunt closing release functions correctly (if installed)

- Make sure that the circuit-breaker's auxiliary contacts function correctly (if installed)

- Make sure that the lock for circuit-breaker in open position (key or padlock) functions correctly (if installed)

8.3.10. Interlocks

- Make sure that the interlocks between circuit-breakers side by side and on top of each other (if applicable) have been correctly

installed and function correctly.