22

5

3

4

2

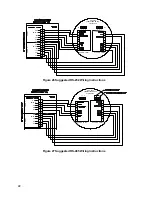

J8 COMM PORT 1

1

NGC 8200

RXD

TXD

RTS

CTS

GND

8 8

10 10

9 9

11 11

12 12

6

7

8

9

1 2 3

J9

2102080-XXX

3 3

5 5

4 4

6 6

7 7

1 1

2 2

SW PWR

CO

M

M

1

CO

M

M

2

TERMINATION BOARD

5

3

4

2

J10 COMM PORT 2

1

6

7

8

9

1 2 3

J11

RXD

TXD

RTS

CTS

GND

SW PWR

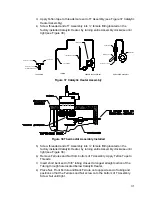

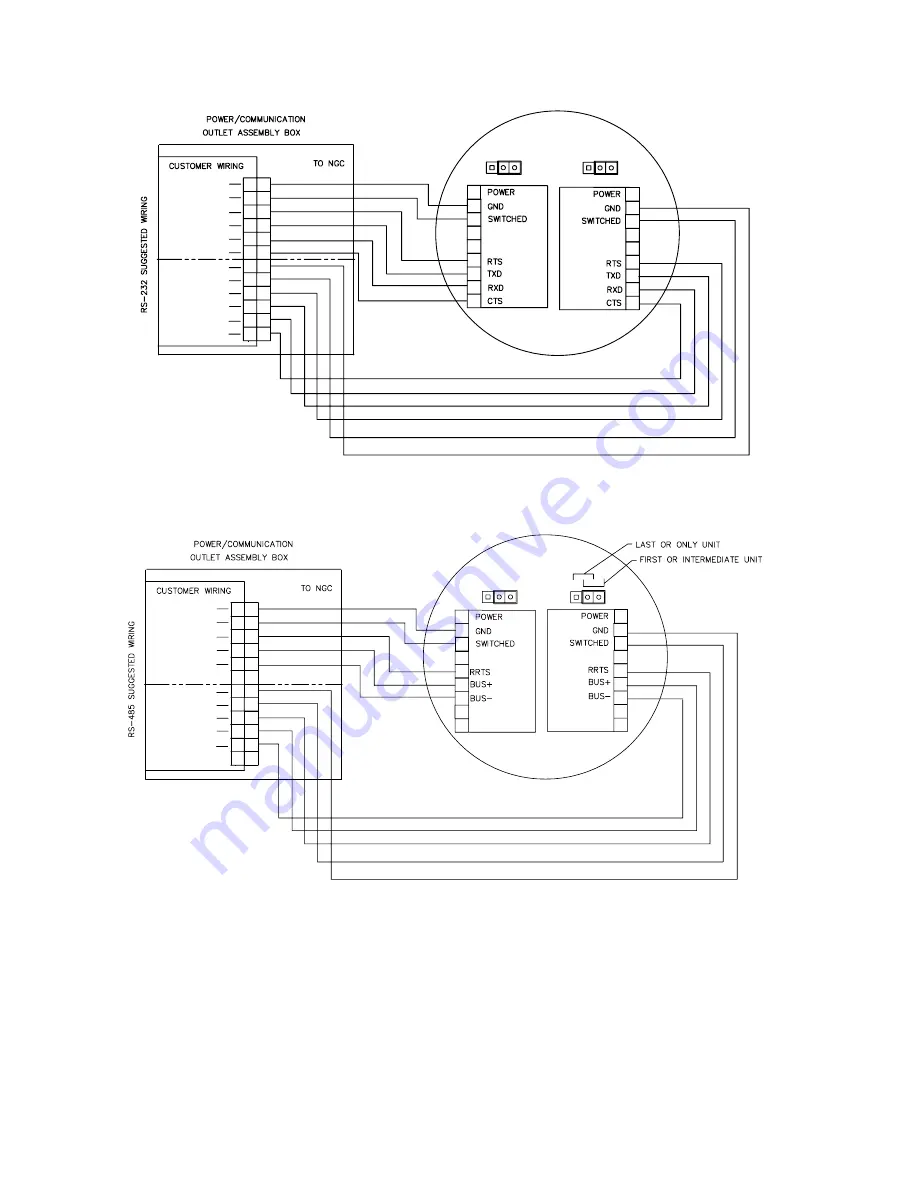

Figure 26 Suggested RS-232 Wiring Instructions

5

3

4

2

J10 COMM PORT 2

1

6

7

8

9

BUS-

BUS+

RRTS

GND

SW PWR

TERMINATION BOARD

NGC 8200

2102080-XXX

1 2 3

J9

1 2 3

J11

5

3

4

2

J8 COMM PORT 1

1

BUS-

BUS+

RRTS

GND

8 8

10 10

9 9

11 11

12 12

6

7

8

9

3 3

5 5

4 4

6 6

7 7

1 1

2 2

SW PWR

COMM

1

C

O

MM 2

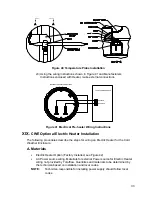

Figure 27 Suggested RS-485 Wiring Instructions