Swirlmeter (TRIO-WIRL S) 2 - 10

PN25080

TRIO-WIRL INSTRUCTION MANUAL

2.5.2 Liquid

The maximum required flowrate should not be less

than 0.5 x Qvmax if possible, but can be set as low as

0.15 Qvmax if required.

1. Convert mass flowrate Qm to actual volume flowrate

Qv

:

ρ

=

Operating density [lb/ft

3

]

Q

V

= Actual volume flowrate [ft

3

/h]

Q

m

= Mass flowrate [lb/h]

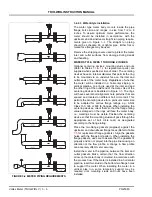

2. Pressure Drop [psi]

See Figure

for water (

ρ

= 8.34 lb/gal)

For other fluid densities the pressure drop can be cal-

culated using the following equation:

∆

p’= Pressure drop fluid [psi]

∆

p = Pressure drop water [psi] (from Figure

)

ρ

= Fluid density [lb/gal] (at operating conditions)

3. Static Pressure

To prevent cavitation when metering liquids a positive

static pressure (back pressure) is required. Its value

can be estimated using the following equation:

p

2

≥

(1.3 x p

Vapor

) + (2.6 x

∆

p`)

p

2

= Positive downstream static pressure [psia]

p

Vapor

=Fluid vapor pressure at operating temperature

[psia]

∆

p` =Fluid pressure drop [psia]

2.5.2.1 Example for Liquids:

Determine the flowmeter size and pressure drop for

metering 18000 gph liquid with a density of 7.50 lb/gal.

1. Refer to Table

to see 3”/ DN 80 meter has a

range of 1320 - 26400 gph

2. Using Figure

, find pressure drop at Qv =

18000 gph and

ρ

= 7.50 lb/gal

∆ρ

` =

psi = 6.3 psi

TABLE 2-3. SWIRL FLOW RANGES, LIQUID

Meter Size

Flow Range

GPH

Frequency

at Q

V

max

[Hz]

Re min

Inch

DN

Qvmin

Qvmax

1/2

15

30

420

185

2100

1

25

120

1560

135

5200

1-1/4

32

240

2640

107

7600

1-1/2

40

420

4200

110

13500

2

50

660

6600

90

17300

3

80

1320

26400

78

15000

4

100

2100

39600

77

17500

6

150

4740

97800

50

35000

8

200

6600

132000

30

44000

12

300

26400

264000

16

118000

16

400

47400

475500

13

160000

QV

Qm

ρ

----------

=

∆

p

'

ρ

8.34

----------

∆

p

×

=

7.5

8.34

----------

7

⋅