Vortex Meter (TRIO-WIRL V) 3 - 10

PN25080

TRIO-WIRL INSTRUCTION MANUAL

FLOWMETER PRIMARY INSTALLATIONS FOR

FLUID TEMPERATURES > 300

o

F (150° C)

In horizontal installations,

when process tempera-

tures above 300

o

F (150

o

C) are encountered, the

meter must be oriented so that the junction box is

located to the side or below meter body, not above.

Refer to Figure

for an example of the recom-

mended high-temperature application orientation.

.

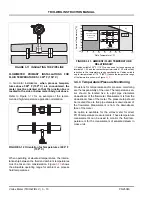

When operating at elevated temperatures, the interre-

lationship between the fluid and ambient temperatures

must be taken into consideration. Figure

shows

the allowable operating range for ambient vs. process

fluid temperatures.

1) Cables suitable 230

o

F (110°C) can be used for the power supply

terminals 31, 32 and the contact output terminals 41, 42 without any

reduction in the temperature range specifications. Cables suitable

only for temperatures of 175

o

F (80°C) reduce the temperature range

of the flowmeter as shown in Figure

3.4.3 Temperature/Pressure Monitoring

Provisions for temperature and/or pressure monitoring

are the responsibility of the user. The temperature sen-

sor should be located five to eight pipe diameters

downstream of the flowmeter. Measurement is from the

downstream face of the meter. The pressure tap should

be located three to five pipe diameters downstream of

the flowmeter. Measurement is from the downstream

face of the meter.

An option is available for the vortex meter for direct

Pt100 temperature measurements. These temperature

measurements can be used to monitor the fluid tem-

perature or for the measurement of saturated steam in

mass units.

FIGURE 3-11 INSULATING THE PIPELINE

FIGURE 3-12 Orientation for Temperatures >300° F

(150

o

C)

Fluid Temperature [°C]

Ambien

t T

emp

eratur

e [

o

C]

1)

Allowable

Temperature Range

HT-Design

≤

400°C

for Std. Design

(

≤

280°C)

Side View, Pipeline

Installation for

Fluid Temperatures > 150°C

-20

FIGURE 3-13 AMBIENT/FLUID TEMPERATURE

RELATIONSHIP