PN25080

Start-Up & Operation 5 - 13

TRIO-WIRL INSTRUCTION MANUAL

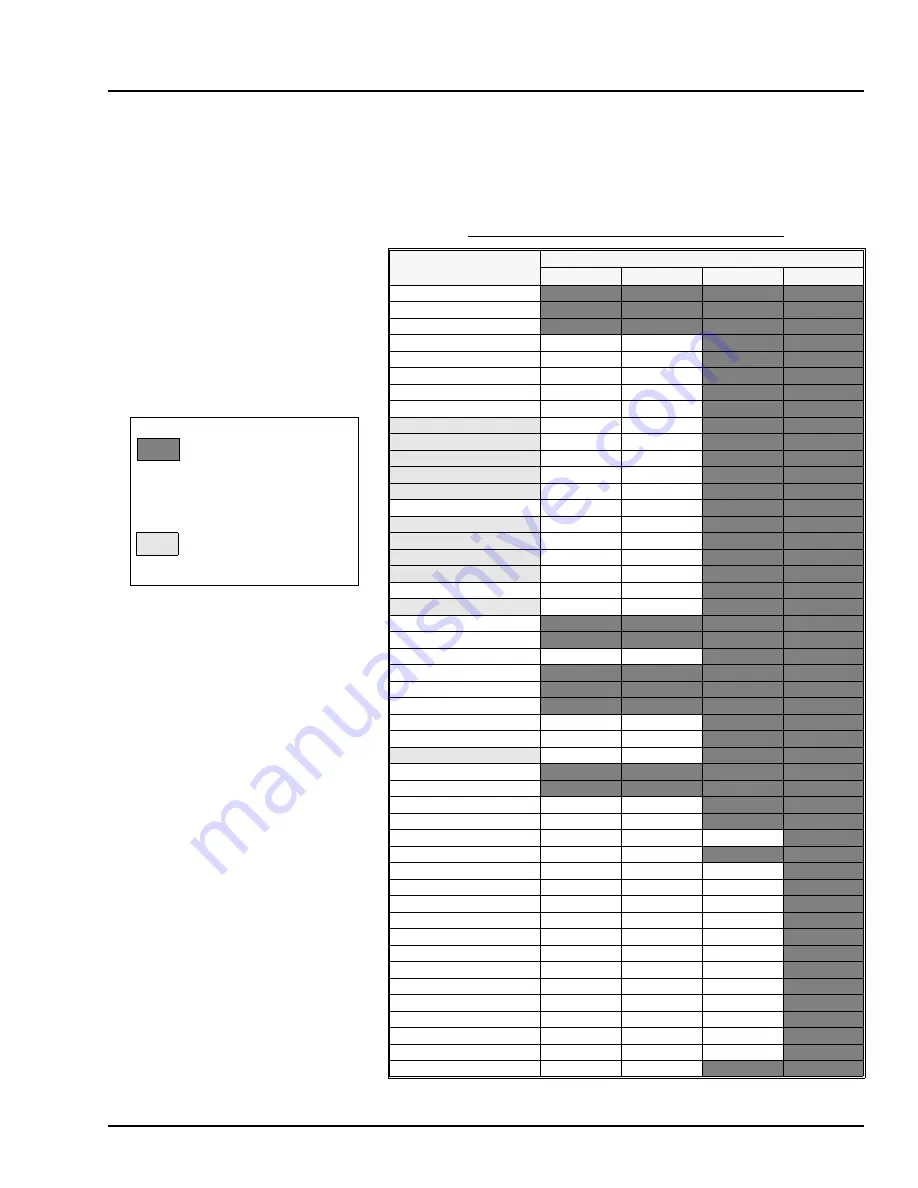

5.5.3 Top-Level Menu Structure

The table to the right lists all of the top-level menus contained in the TRIO-WIRL firmware vs. the four menu pro-

gramming modes:

TABLE 5-1. TOP-LEVEL MENU STRUCTURE

Menu Item

Menu Programming Levels/Modes

Locked

Standard

Specialist

Service

Program Level

Prog. Protection Code

Language

Primary

Meter Size

Median K-Factor

Schedule Correction

Flow Mode

Unit Density

Reference Density

Normal Density

Compressibility

Standard Conditions

Unit Temperature

Reference Temperature

Unit Pressure

Pressure P

oper

ABS

Volume Extension

Unit Q

vol

Unit Q

m

QmaxDN Oper

Qmax

Qmin Operating

Totalizer

Damping

Hardware Config.

Iout at Alarm

Pulse Factor

Pulse Width

Display

Error Register

Self Check

Instr. Address

Instrument No.

Order No.

PT100 Sensor

Linearization

D-Base Handling

Init Flash

Flash Checksum

Adjust I=4mA

Adjust I=20mA

Min. Current

DSP Par

Vib Par

Temp Par

Service Display

TRIO-WIRL Firmware ID

Indicates the available

menus for the given pro-

gramming mode.

Indicates

Menu Items

that appear depending

on other menu selec-

tions.