Commissioning

34 TTF300

OI/TTF300-EN

6 Commissioning

Important

The LC display is ready for operation as soon as the temperature sensor has been mounted

and the connections have been installed.

The connected wires must be checked for firm seating. Only firmly seated wires ensure full

functionality.

K

7 Configuration

7.1

Configuration types

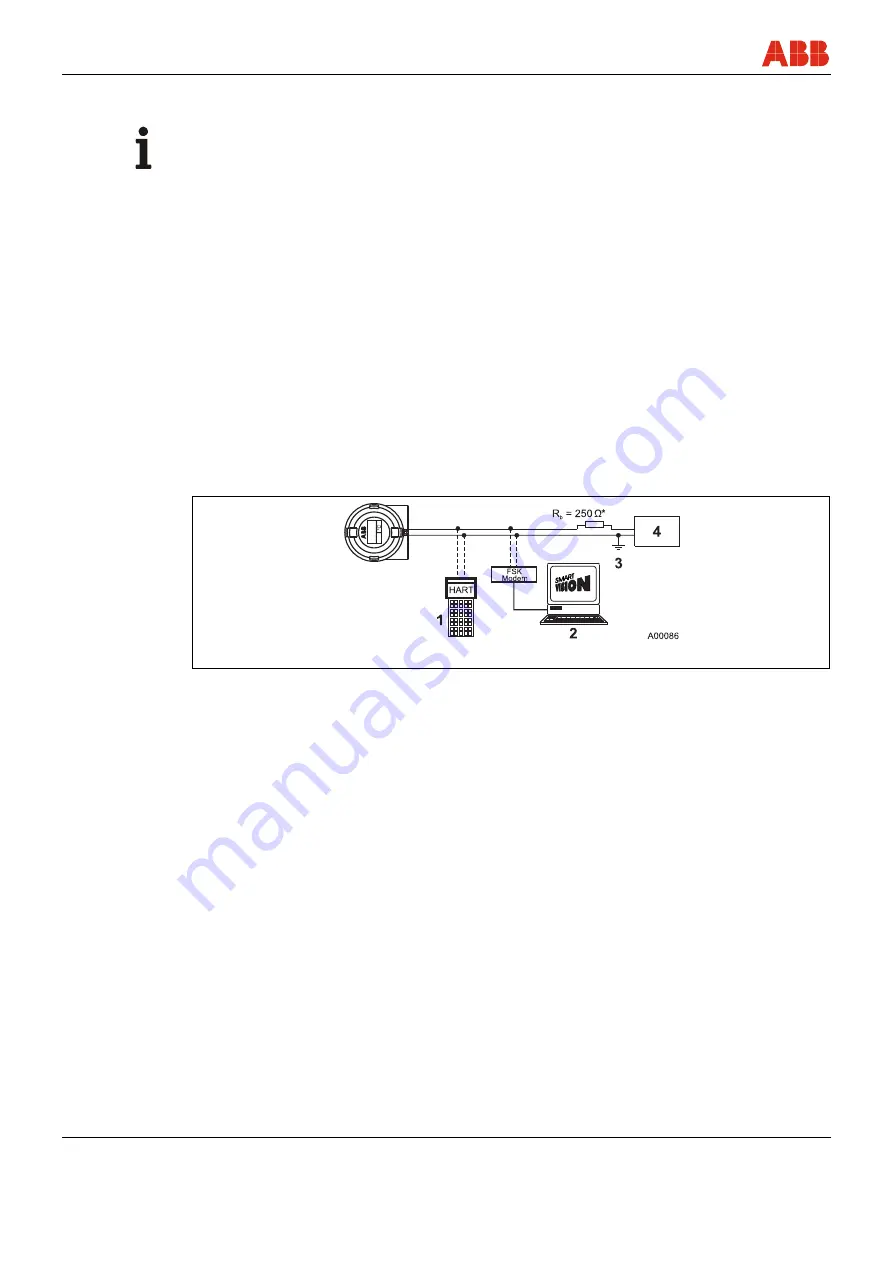

There are a variety of configuration options for the transmitter.

• via optional, plug-on LCD display with control buttons.

• via HART protocol and handheld terminal

• Via HART protocol with FSK modem, PC, and SMART VISION configuration software.

• Via DTM in FDT 1.2 frame applications.

• Configuration via fieldbus (PROFIBUS), if the superordinate remote I/O system is HART-

enabled (e.g., ABB S800 or S900).

* If necessary

Fig. 20

1

Handheld terminal

2

FDT / DTM technology

3

Ground connection (optional)

4

Power unit (process interface)

7.1.1 HART

communication

Communication with the transmitter takes place using the HART protocol. The communication

signal is modulated on both wires for the power supply line and decoded by the transmitter. The

electrical connection is provided either by two test pins at the (+) and (–) terminals of the

transmitter or by the power supply cable that is installed on-site. The advantage of this is that

remote configuration is possible with supply units that are part of the industrial plant.