TTR200

| OI/TTR200-EN Rev. B 15

8

Commissioning

8.1

General remarks

In case of corresponding order the transmitter is ready for

operation after mounting and installation of the connections.

The parameters are set at the factory.

The connected lines must be checked for firm seating. Only

firmly seated lines ensure full functionality.

8.2

Checks prior to commissioning

The following points must be checked before commissioning

the device:

— The wiring must have been completed as described in

chapter "Electrical connections" on page 8.

— The ambient conditions must meet the requirements set

out on the name plate and in the Datasheet.

8.3

Basic Setup

Communication with the transmitter takes place using the

HART protocol. The communication signal is modulated onto

both wires of the signal line in accordance with the HART FSK

"Physical Layer" specification.

The electrical connection is provided at the (+) and (–)

terminals of the transmitter or by the power supply cable that

is installed on-site. The advantage of this is that remote

configuration is possible with supply units that are part of the

industrial plant.

The following configuration types are available for the

transmitter:

— With the handheld terminal

The connection of the cable for the handheld terminal is

performed without polarity. The transmitter can also be

configured via the HART protocol during normal operation.

— With

DTM

Configuration can be performed within an FDT frame

application that is approved for use with the DTM.

— With

EDD

Configuration can be performed within an EDD frame

application that is approved for use with the EDD.

9

Operation

9.1

Safety instructions

If there is a chance that safe operation is no longer possible,

take the device out of operation and secure it against

unintended startup.

9.2

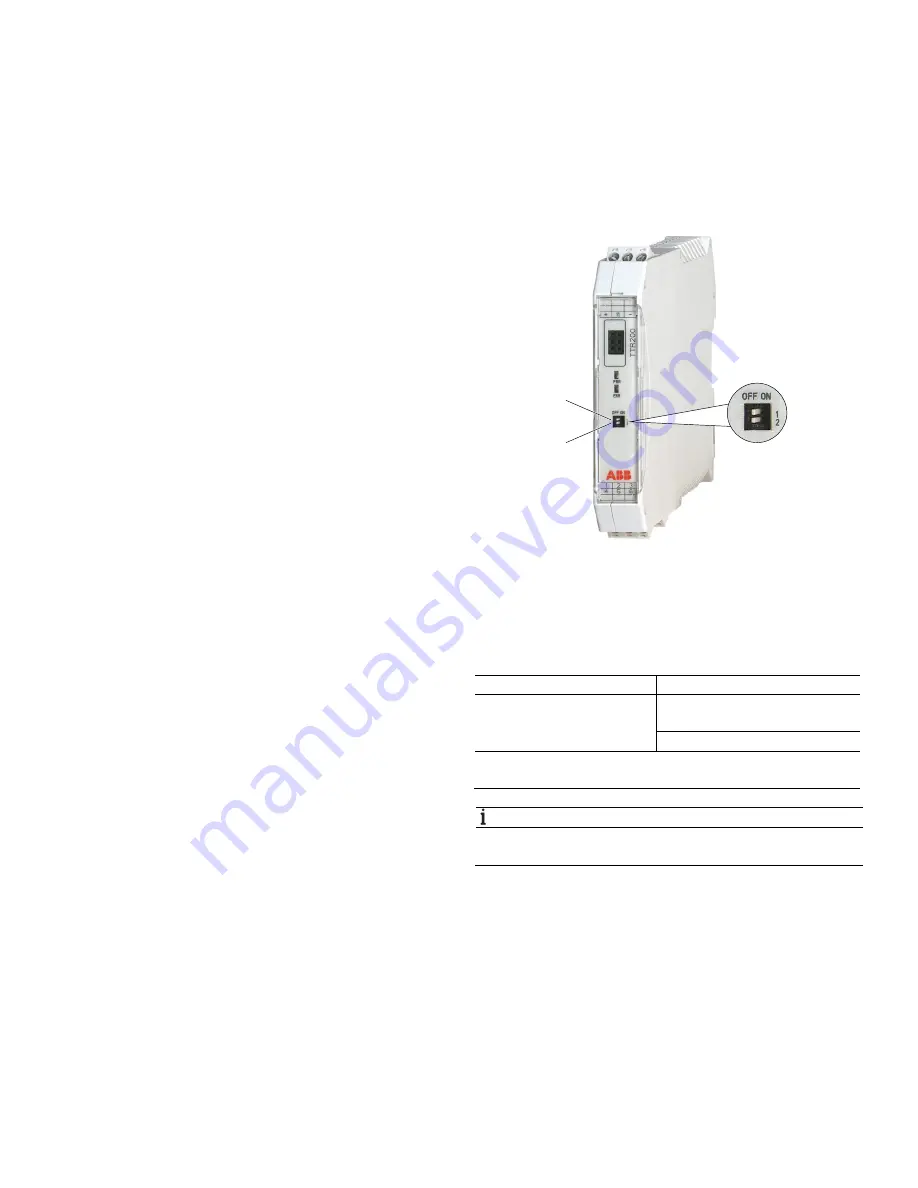

Hardware settings

Fig. 12

a

DIP switch 1

b

DIP switch 2

The transmitter has two DIP switches.

Switch 1 activates the hardware write protection.

Switch 2 has no function.

DIP switch

Function

1 Local write protection

Off: Local write protection

deactivated

On: Local write protection activated

2 Without

function

NOTICE

—Factory settings: Both switches "OFF". Local write

protection deactivated

A11161

2

1