Safety

OI/TTR200-EN TTR200

5

Pos: 4.1 /Überschriften/1/S - U/Sicherheit @ 0\mod_1129703894050_3101.doc @ 3168

1 Safety

Pos: 4.2 /Sicherheit/Allgemein/Organisatorische Maßnahmen/Hinweise zur Verwendung der Betriebsanleitung @ 18\mod_1203689776329_3101.doc @ 164715

Read these operating instructions carefully prior to installing and commissioning the device.

These instructions are intended as an overview and do not contain detailed information on all

designs for this product or every possible aspect of installation, operation and maintenance.

For additional information or in case specific problems occur that are not discussed adequately

in these instructions, contact the manufacturer. The content of these instructions is neither part

of any previous or existing agreement, promise or legal relationship nor is it intended to change

the same.

All obligations of ABB Automation Products GmbH are created by the relevant sales agreement,

which contains the complete and solely binding warranty regulations. These contractual

warranty provisions are neither extended nor limited by compliance with this manual.

Pos: 4.3 /Sicherheit/Allgemein/Allgemeines zur Sicherheit @ 0\mod_1129703939516_3101.doc @ 3260

1.1 General

Safety

Information

The “Safety” chapter provides an overview of the safety aspects to be observed for the

operation of the device.

The device is built based on state-of-the-art technology and is operationally safe. It was tested

and left the factory in a proper state. The requirements in the manual as well as the

documentation and certificates must be observed and followed in order to maintain this state for

the period of operation.

The general safety requirements must be complied with completely during operation of the

device. In addition to the general information, the individual chapters of the manual contain

descriptions about processes or procedural instructions with specific safety information.

Only the observance of all safety information enables the optimal protection of personnel as well

as the environment from hazards and the safe and trouble-free operation of the device.

Pos: 4.4 /Sicherheit/Temperatur/Allgemein/Bestimmungsgemäße Verwendung (Temperatur, Messumformer) @ 8\mod_1173276365022_3101.doc @ 71437

1.2 Intended

use

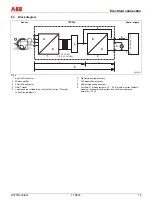

This device is intended for the following uses:

•

To measure the temperature of fluid, pulpy or pasty substances and gases or

resistance/voltage values.

The following items are included in the intended use:

•

Read and follow the instructions in this manual.

•

Observe the technical ratings (refer to the section “Technical data” or data sheet).

Pos: 4.5 /Sicherheit/Allgemein/Hinweis zur bestimmungswidrigren Verwendung (Wartung/Reparatur) @ 0\mod_1129707002440_3101.doc @ 3240

Repairs, alterations and enhancements or the installation of replacement parts is only

permissible as far as described in the manual. Further actions must be verified with ABB

Automation Products GmbH. Excluded from this are repairs performed by ABB-authorized

specialist shops.

Pos: 4.6 /======= Seitenumbruch ======== @ 0\mod_1126532365768_3101.doc @ 3830