4

User's manual UBB

|

1ZSE 5492-156 en, Rev. 4

Introduction

The UB range of on-load tap-changers manufactured by ABB

has been developed over many years to provide maximum

reliability. The simple and rugged design gives a service

life equal to the service life of the transformer. Minimum

maintenance is required for trouble-free operation. The only

parts requiring maintenance are contacts that might need

replacement during the service life, the insulating oil and the

motor-drive mechanism.

The design allows ready access to all parts, making

inspection and maintenance quick and simple.

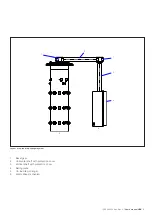

The on-load tap-changers, type UB, is housed in the

transformer tank. The motor-drive mechanism, type BUE or

BUL, is attached to the transformer tank and connected to

the tap-changer by means of drive-shafts and a bevel gear.

Safety warnings

The following warnings and notes are used in the manual:

WARNING

WARNING indicates an imminently hazardous

situation, which if not avoided will result in death or

serious injury. This signal word is to be limited to the

most extreme situations.

WARNING also indicates a potentially hazardous

situation, which if not avoided could result in death or

serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation,

which if not avoided may result in minor or moderate

injury. It may also be used to alert of unsafe practices.

CAUTION may also indicate property-damage-only

hazards.

Safety precautions

WARNING

Personnel operating and inspecting the tap-changer

must have good knowledge of the apparatus and

must be aware of the risks pointed out in this manual.

Personnel making electrical connections in the motor-

drive mechanism have to be certified.

WARNING

Small amounts of explosive gases might come out

from the breathing devices (dehydrating breather

or one-way breather). Make sure that no open

fire, hot surfaces or sparks occur in the immediate

surroundings of the breathing devices.

CAUTION

After a trip from a supervisory device, an inspection

must be made by a specialist. The diverter switch

housing must be drained and the diverter switch lifted

and carefully investigated before the transformer is

reenergized.