24

3 Installation in the Transformer

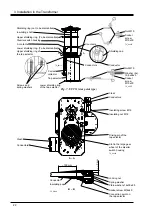

8. Remove the transport locking and the lifting eyes with fasteners from the top

section of the tap selector, see Fig. 8.

CAUTION

Do not operate the tap selector until it is connected to the diverter switch housing.

Screw (to be removed)

Transport locking

(to be removed)

TC_00216

Lifting eyes with

fasteners

(to be removed)

Fig. 8.

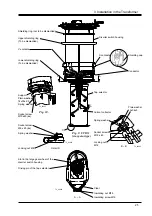

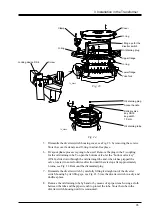

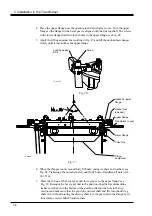

9. Lift the diverter switch housing in position and fit the tap selector to the diverter

switch housing, see Fig. 4. The tap selector driving pin shall fit into the large gear

wheel slot, see Fig. 9, A-A.

CAUTION

The driving crank on the tap selector must not be moved more than slightly to engage

the slot in the large gear wheel of the diverter switch housing.

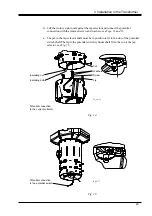

10. Insert four M10x40 screws and washers, see Fig. 10, through the tap selector

upper part to the four supports of the diverter switch housing. Tighten the screws.

WARNING

The diverter switch housing and the tap selector contains moving parts. Be

cautious!

11. Connect the supplied conductors between the diverter switch housing and tap

selector, see Fig. 9. The conductor ends and their connecting points have the

same markings. Fasten the conductors with cleats, see Fig. 9, A-A. The number

of conductors is varying depending on the rated through current and the type of

connection.

12. If the impulse withstand voltage to earth exceeds 380 kV, insulate the connections

on the tap selector by winding paper around them to a thickness of

approximately 3 mm, see Fig. 7, B-B. The paper shall be of the same quality as

used for insulation of conductors within the active part of the transformer.

13. If the impulse withstand voltage to earth exceeds 380 kV, mount the supplied

shielding ring (DS10) at the bottom plate of the tap selector, see Fig. 9, detail D.

CAUTION

After mounting the shielding ring, the on-load tap-changer must

not

stand on the

shielding ring.

14. Continue with section 3.3.