31

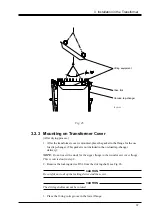

3 Installation in the Transformer

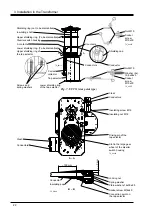

Insulating screws

and nuts M16

V-contacts

Plain washer

13x34x3

Locking nut

M12

Spring washer

Socket screw

M12 x 45

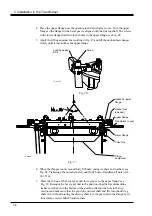

A A

C C

Driving pin of the

tap selector

Slot in the large

gear wheel of the

diverter switch

housing

Spacer (Al) Ø40

The tap selector

can be delivered

with mechanical

end position barrier.

Fig. 17. UCD.N

(star point type)

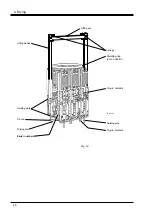

Cleat

TC_00117

X-contacts

Cleat

B B

Fig. 18.

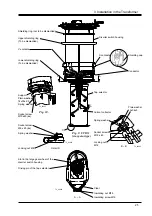

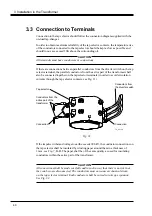

A

A

Current collector

Shielding ring (to

be dismantled)

Shielding ring

(not to be

dismantled)

Diverter switch

housing

C

Plain washer

13x34x3

Socket screw

M12 x 50 (6x)

Spring washer

Conductor

Shielding cap

Insulating

screws

M16x130

and nuts

Conductors

C

Tap selector

B

B