- 80 -

UMC22-FBP

Universal Motor Controller UMC22-FBP

Software version 4.0

FieldBusPlug / Issue: 02.0008

V 6

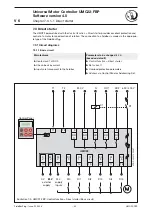

7.1.3 Interface and data overview

Hardware Inputs / Outputs

Chapter 7.1.3~1 Transparent

Terminal

13

14

15

16

17

18

Device input

(to bus)

DI0

DI1

DI2

DI3

DI4

DI5

Terminal

7

8

9

Device output

(from bus)

DO0

DO1

DO2

2)

(fault output)

Monitoring telegram, digital

Bit No.

7

6

5

4

3

2

1

0

Byte 0

WARNING

FAULT

-

-

-

-

-

-

Byte 1

DI5

(UMCinput)

DI4

(UMCinput)

DI3

(UMCinput)

DI2

(UMCinput)

DI1

(UMCinput)

DI0

(UMCinput)

-

-

Monitoring telegram, analog

Byte 0 and Byte 1: Motorcurrent in % of set current

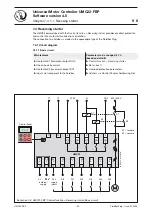

Command telegram, digital only

Bit No.

7

6

5

4

3

2

1

0

Byte 0

-

FAULT

RESET

-

PREPARE

EMERGENCY

START

SELF

TEST

-

-

-

Byte 1

DO2

1)

(UMC output)

DO1

(UMC output)

DO0

(UMC output)

-

-

-

-

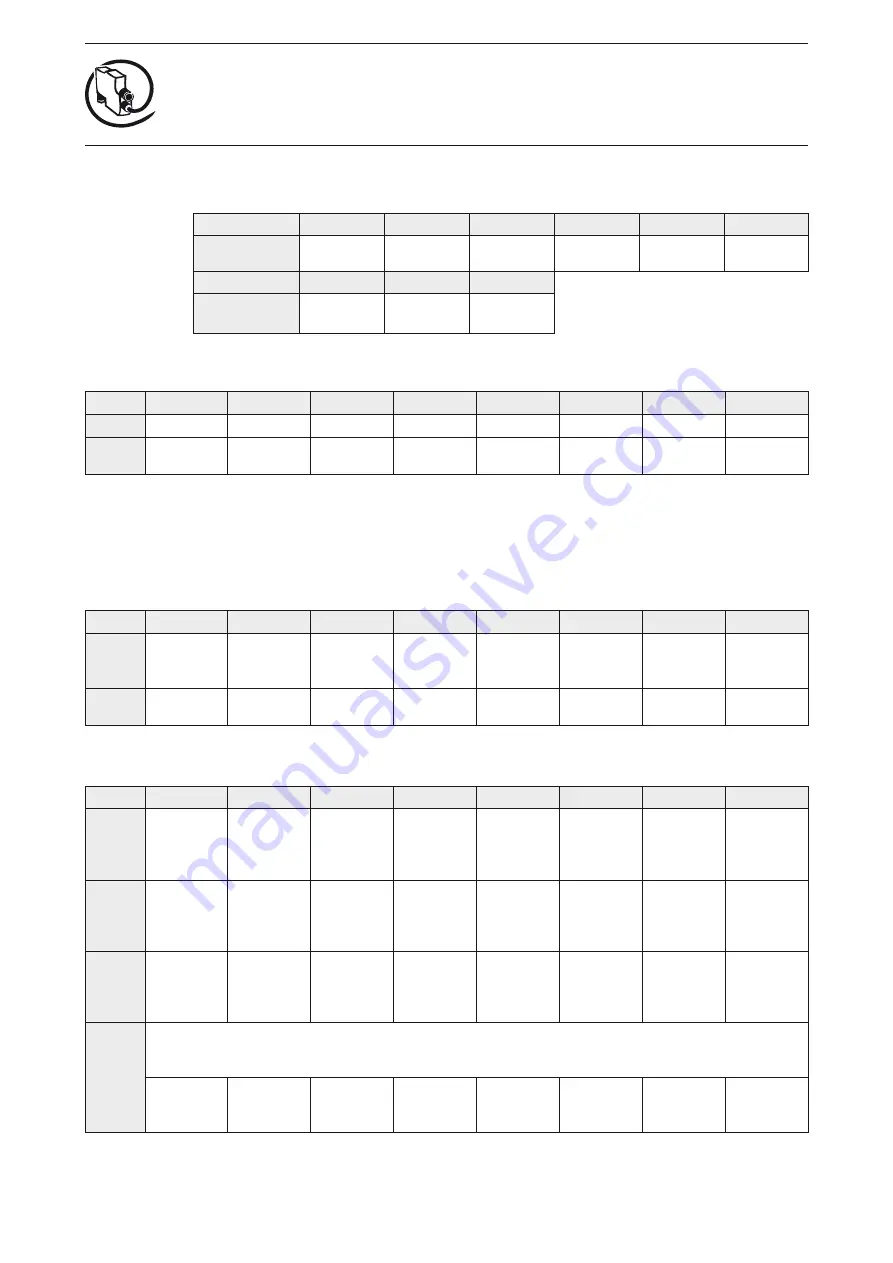

Diagnosis telegram

Bit No.

7

6

5

4

3

2

1

0

Fault

Byte 0

-

Self test failed

F010

2)

Fault signal

on DI0, DI1

or DI2

1)

F011

2)

-

-

-

-

-

Fault

Byte 1

Overload (trip)

fault

trip

2)

-

Communi-

cation fault

F003

2)

Parameter out

of range

F004

2)

-

-

-

-

Warning

Byte 2

Motor current

high threshold

1)

Motor current

low threshold

1)

-

Self test

running

buSy

2)

-

Self test

running

buSy

2)

Emergency

start

prepared

-

Warning

Byte 3

If Parameter out of range: Pamameter number (leading two stages of the parameter, e.g. "02" Current factor)

If Self test fauled: Self test error number (only for service)

In all other cases:

Phase loss

trip

2

Fault on DI2

F024

2)

Faut on DI1

F023

2)

Fault on DI0

F022

2)

Earth fault

F020

2)

PTC

short-circuit

F019

2)

PTC

wire break

F018

2)

PTC

temperature

F017

2)

1)

depending on parameterization

2)

displayed on the Control Panel

Busdata details see 4.2.2.

Summary of Contents for UMC22-FBP

Page 167: ......