44

ABB Power Distribution

6

Operation of the ZS1 switchgear

The relevant work and operating procedures are to

be carried out carefully by trained specialists familiar

with the installation, taking into account all relevant

safety regulations according to DIN VDE/IEC and

other relevant professional bodies, and other local

and works regulations and instructions. Special

attention should also be paid to full compliance with

VDE 0105 (Operation of electrical installations).

6.1

Start-up

6.1.1

Preparatory work

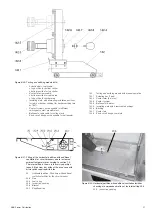

(Figures 3/10, 3/20 and 6/20)

In preparation for commissioning, the following

work should be carried out prior to connection with

the high-voltage power supply:

• Check the general condition of the switchgear

for detrimental circumstances of all kinds.

• Perform a visual examination of the switching

devices, withdrawable parts, isolating contacts,

insulating parts, etc.

• Check the connection of the main earthing bar

with the station earthing conductor (DIN VDE

0141).

• Check the paintwork for damage and touch up

as described in section 7.4.1 where necessary.

• Remove all material residues, foreign bodies and

tools from the switchgear.

• Clean the switchgear, rubbing down insulating

parts with a clean, soft, non-fraying and dry

cloth. Remove greasy or adhesive dirt as

described in section 7.3.

• Properly refit all covers, etc., removed during

assembly and testing processes.

• White transport caps 13.9 on the poles of vacuum

circuit-breakers, where fitted, must be removed.

• Pole tube caps 13.10 may be fitted to the

vacuum circuit-breakers in certain switchgear

installations and with breakers of certain types.

Their proper fit should be checked.

• Lifting lugs 13.13 for high-current circuit-

breakers, if still fitted, must be removed.

• Perform AC voltage testing on the main circuits

to VDE 0670, Part 6 (IEC 60298) as far as

necessary. Pay special attention during this

procedure to voltage transformers and cables

etc. A testing and earthing withdrawable part

142 can be used to establish the connections.

• Switch the auxiliary and control voltage on.

• Carry out test operations of switching devices

manually or by electrical control, and simul-

taneously observe the relevant position

indicators.

• Check mechanical and electrical interlocks for

effectiveness, without using force.

• Set the protective devices in the panel to the

required values, and check their functioning with

test equipment.

• In panels with an additional ventilation system

due to increased ambient temperature

according to section 1.3 (figures 6/21 and 6/22),

the flap 20.3 hanging in partition 20 must loosely

rest against leaf spring 20.4 (with the centrifugal

fan at a standstill if fitted):

To check:

– Insert a suitable screwdriver through opening

20.5 in horizontal partition 20 and into bracket

20.6 on flap 20.3.

– Swing flap 20.3 upwards and allow it to rest

loosely again on leaf spring 20.4.

– If the flap is in the blocked position, use the

screwdriver to press leaf spring 20.4

downwards by approx. 5 mm to release the

block before swinging the flap.

– If any centrifugal fans controlled in relation to

primary current are fitted, also check that they

function correctly.

• On motor-driven withdrawable parts, check the

direction of rotation of the travel motors as

described in section 7.5.1.

• For any further questions on the functions of the

withdrawable circuit-breaker part and its testing,

see section 7.5.

• Instruct the local operators in the fundamental

details of regular handling of the switchgear.

• Check on the operational readiness and

switching status of electrical systems upstream

and downstream from the switchgear.

From areas bordering on the switchgear, in

accordance with responsibilities, check on the

following where applicable:

• Power cables

• Auxiliary cables

• Auxiliary power source

• Remote control

• Entire earthing installation, according to DIN

VDE 0141

• Switchroom equipment

• Switchroom condition.

6.1.2

Start-up

• Comply with all relevant safety regulations.

• Ensure that the circuit-breakers and switch-

disconnectors in the switchgear are in the OFF

position.

• Remove any existing earthing and short-circuit-

ing connections in the critical switching area.

• Energize the feed cables.

• Connect the switchgear, step-by-step, observing

the signals and indicators.

Summary of Contents for UniGear ZS1

Page 66: ...ABB Power Distribution 67 ...