ABB Power Distribution

59

Checking of the readiness for operation can

be carried out as follows:

a) Load-dependent functional test with

controllable primary current injection of the

relevant instrument transformer. At current

rise:

1. to approx. 70% of the rated instrument

transformer current, the fan must start,

and

2. to 80 % of the rated instrument

transformer current, the fan must have

reached the required minimum air flow.

Corresponding monitoring/signalling by

the wind vane with microswitch.

b) Basic checking with temporary operation of

the centrifugal fan with an external power

supply of 220 V AC.

c) In both cases, check for unimpeded normal

running of the fan and listen for any unusual

bearing noise. Remove any dirt on the fan

rotor.

d) Check the unimpeded function of the wind

vane and microswitch by starting the fan

several times.

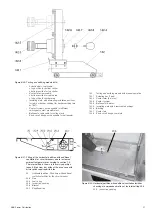

e) The wiring to the removable horizontal

partition 20 can be disconnected behind

the right-hand side duct cover 43.4 (figure

3/13). Observe the circuit diagram and

carefully reconnect the wiring on

completion.

Caution:

instrument transformer circuit.

• With regard to the switching devices, their sepa-

rate Instruction manual should be observed.

• Check all switchgear accessories and auxiliary

facilities (e.g. storage batteries).

• No external discharge may occur on the

surfaces of equipment at operating voltage. This

can, for example, be detected by characteristic

noises, a clearly perceptible smell of ozone, or

visible glowing in the dark.

• Visual checking of the contact system. We

recommend to turn alternately the contact

system in order to clean the inner contact points

of the contact system.

The contact points should be cleaned if signs of

unperminable overheating (discoloured surface)

are visible (see section 7.4).

• If irregular conditions are detected, then cor-

responding repair measures should be initiated.

7.3

Servicing

If, on the occasion of an inspection in accordance

with 7.2, the necessity of cleaning measures has

been established, proceed as follows:

• Before cleaning, where required, the working

area must be switched off and secured against

reconnection in accordance with the „Safety

Regulations“ specified by DIN VDE/IEC.

• Cleaning the surfaces in general:

– Weakly adhering dry dust deposits with a soft

dry cloth.

– More strongly adhering grime with mildly

alkaline household cleanser or with Rivolta

BWR 210.

• Cleaning insulating surfaces and conductive

components:

– Minor pollution with Rivolta BWR 210.

– Strongly adhering pollution with Cold cleanser

716.

• Observe the manufacturers’ directions and in

particular ABB Instruction manual BA 1002/E

and BA 1006/E on safety at work.

• Wipe down after cleaning, using clean water,

and dry properly.

• Should external discharges occur as a result of

condensation, application of a thin silicone film

on the surface concerned is often effective as a

temporary remedy. It is advisable to request

advice from the ABB after-sales service

department on permanent solutions to such

unusual problems.

7.4

Repair

7.4.1

Switchgear in general

Repair of surface damage:

• Carry out repair work immediately after a defect

has been discovered.

• Completely remove all rust from damaged paint-

work areas on steel sheet and other steel parts

by mechanical means, e.g. with a wire brush.

Lightly grind the surrounding paint coat and care-

fully degrease the entire area. Then immediately

apply an anti-rust primer and, after an appropriate

hardening time, apply the top coat. Only use

suitable and compatible paint products.

Apply the top coat in standard colour RAL 7035,

or the relevant special colour.

Summary of Contents for UniGear ZS1

Page 66: ...ABB Power Distribution 67 ...