ABB Power Distribution

9

3

Panel design and equipment

3.1

Basic structure and variants

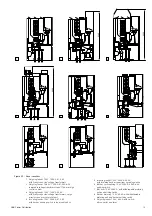

(Figures 3/1 to 3/5)

The basis for the ZS1 panel is the incoming/

outgoing feeder panel with vacuum circuit-breaker

using insertion technology. It is divided into busbar

compartment A, circuit-breaker compartment B,

cable compartment C and the control cabinet for

the secondary equipment D. Apart from this, there

are variants for all operating needs. The pictures 3/

1 to 3/5 show possible configurations of a panel

including electrical equipment.

For a busbar sectionalizing, two panels are

necessary, the coupling panel with the

withdrawable circuit-breaker part and a bus riser

panel (optional with busbar metering and earthing).

When setting up the switchgear in two rows, the

busbar sectionalizing can be combined with a bar

connection between the two sets of switchgear. In

equipment without busbar sectionalizing, a direct

bar connection between the busbars will be

established.

With ZS1 panels it is possible to set up a double

busbar installation in accordance with the two

breaker method. This duplex arrangement is

possible both with back to back or front to front

positioning.

Apart from this, panels with fixed-mounted

switch-disconnectors of type C3 (e.g. for feed to

a station service transformer) are provided.

Depending on rated short-time current and the

ceiling height of the circuit-breaker compartment, a

pressure relief duct on the panel would perhaps be

required.

Further details about the installation and equipping

of the switchgear can be obtained from the order

documents.

3.2

Enclosure and partitioning

(Figure 3/5)

Enclosure and internal partitioning of the panels are

of high quality aluminium-zinc coated steel sheets,

2 mm thick. The three high voltage compartments

(busbar compartment circuit-breaker compartment

and cabel connection compartment) are equipped

with top-mounted, secured pressure relief flaps.

These open in the case of overpressure due to an

internal arc fault.

The front of the panel is closed off by pressure

resistant doors which open to an angle of almost

180

°

. Cable and circuit-breaker compartments

have their own doors equipped with sight glasses

made of security glass. Neighbouring panels are

partitioned from one another by the side walls of

each panel and the air cushion which remains

between these walls as a result of the design when

the panels are joined together.

In the case of the duplex version with a rated short-

time current of up to 31,5 kA a swivelling lever cap

is used instead of the three screw caps. The door

of the control cabinet has a catch fastener lock.

The enclosure is completed by top-mounted

pressure-relief flaps which are, according to the

rated tee-off conductor current, made of sheet

steel 49.2 or expanded metal 49.1 and below by

means of the floor-covering 17 made of sheet steel

which cannot be magnetized. The pressure-relief

flaps are secured with steel screws on one longitu-

dinal side and on the other longitudinal side with

plastic screws. In the case of internal overpressure,

the plastic screws are the point of rupture.

Part of the internal partitioning are the busbars-rear

wall 9.3, the intermediate wall 9, the mounting plate

12 with the shutters 12.1. and the horizontal

partition 20. The internal partitioning makes it

possible to have safe access to the circuit-breaker

and cable compartment even when the busbars

are live.

The control cabinet for the secondary equipment is

completely protected from the high voltage area

due to its steel-sheet casing.

On the front side, cover plates ensure a good

appearance and are mechanically and thermically

arc fault proof in case of such an event in the end

panel.

Doors and rear walls as well as the cover plates are

thoroughly cleaned and treated against corrosion

before receiving a high-quality double coating of

paint. The finishing coat is in the standard colour

RAL 7035 (special colours by agreement). The

stoving procedure completes the work and imparts

a notable insensitivity to impacts and corrosion.

3.2.1

Ventilation of the panels

(Figures 3/1, 3/5, 3/9)

For the purpose of ventilation in cases of certain

rated currents in the busbar and tee-off bars,

openings in the outer enclosure are necessary.

For incoming air to the circuit-breaker com-

partment, the horizontal partition is provided with

air-vents 20.2. The degree of protection IP4X and

safety in case of releases of hot gas caused by an

arc fault are provided by the flap 20.3 in the raised

false floor. In the case of outgoing air, the presssure

relief flaps are provided made of expanded metal

instead of clad metal sheets. The form and size of

the vents in the expanded metal provide the degree

of protection IP4X.

In the panel for tee-off rated current 4000 A, cross-

current blowers are installed for cooling purposes.

Summary of Contents for UniGear ZS1

Page 66: ...ABB Power Distribution 67 ...