In addition to the notes below, please read and follow the safety and installation information

provided in the installation manual. The technical documentation and the interface and

management software for the product are available on the website.

This equipment must be used following the guidelines provided in the manual.

Failure to do so may impair the inverter safety features.

Quick installation guide

UNO-2.0/3.0/3.6/4.2-TL-OUTD

(from 2.0 to 4.2 kW)

ABB solar inverters

1.

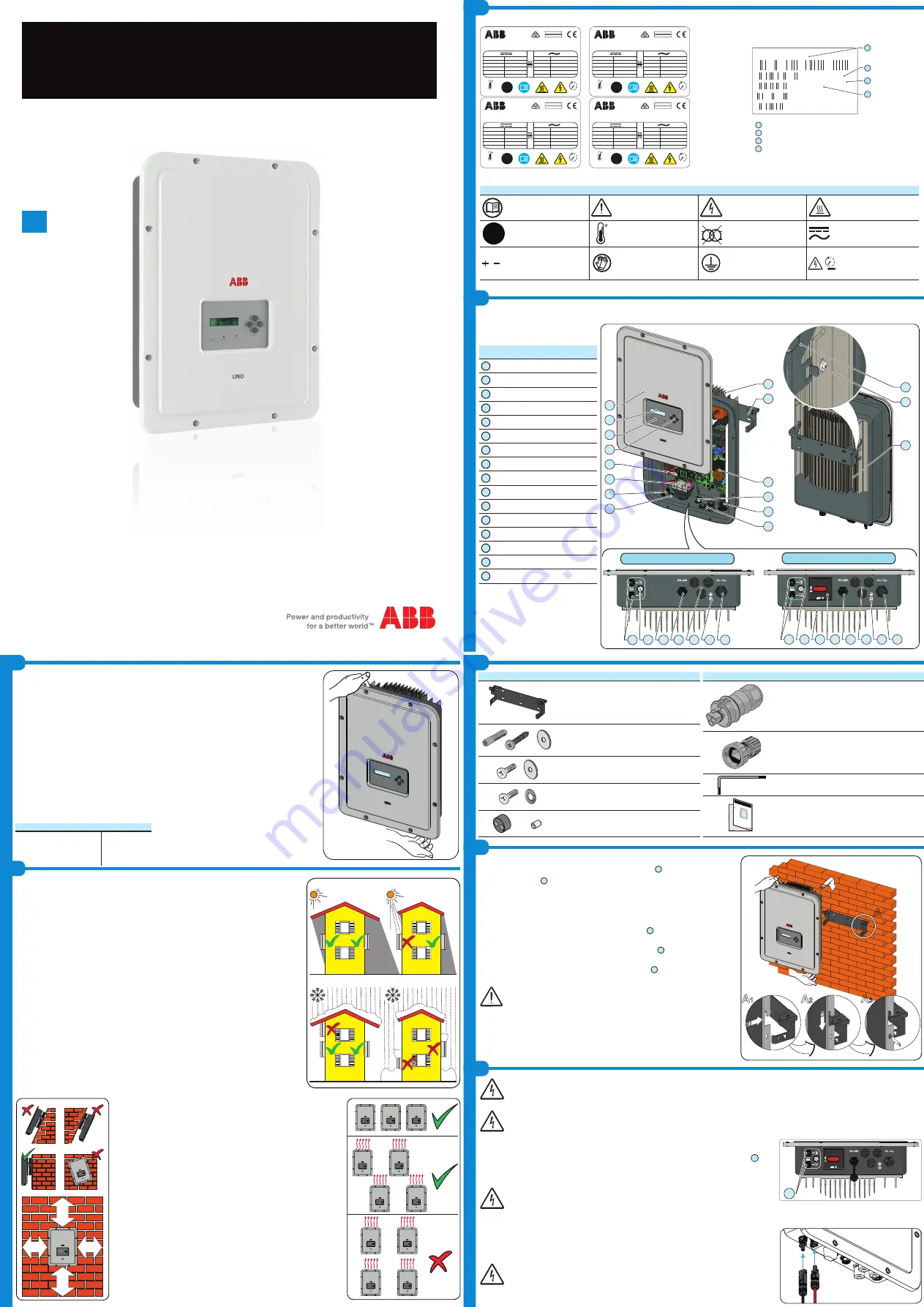

Labels and Symbols

Inverter Models and Components

2.

Lifting and transport

3.

EN

Assembly Instructions

6.

List of components supplied

5.

Choice of installation location

4.

7.

Input connection (DC)

The labels on the inverter carry the branding, the main technical data and the identification of the equipment and the manufacturer

A4

1:1

1/1

AA

A.Statuti

A.Butini

29/05/2015

G.Fiesoli

Pantone

Process Cyan C

Process Yellow C

LABEL MATERIAL:

3M type 7331 (UL R/C, PGJI2)

INKS:

Refer to UL File MH16411

LABEL CONTENT:

Fixed as shown in the picture

SIZE:

63 mm (height) x 90 mm (width)

29/05/2015

29/05/2015

29/05/2015

C.Granci

All

material

used

and finished product, must meet the requirements of the current RoHS

recti

i

ve 2002/95/EC.

Title

Issued

Modified

D

D

esign approved

Elec. Eng. approved

Mfg. approved

Size

Scale

Dim. in mm

Sheet

Drawing No.

Revision

© Copyright 2014 Power-One Italy Spa. All rights reserved. Reproduction, use or disclosure to third parties without express written authority is strictly forbidden.

Regulatory Label of UNO-2.0-TL-OUTD

UNO LOW COST (V1N)

XLP.V1N02.0AL

MODEL:

UNO-2.0-TL-OUTD

IP65

5 minutes

-25 to + 60 °C

-13 to +140 °F

INVERTER

SOLAR

www.abb.com/solar

600 V

80 - 580 V

12.5 A

180 - 500 V

16 A

230 V 1Ø

50 Hz

1800 W @ 45 °C amb.

2000 W @ 45 °C amb.

10 A

2000 VA

V

dc max

I

dc max

V

dc MPP

V

dc, Full Power

I

sc max

V

acr

f

r

I

ac max

P

acr (cos = ± 0.9)

φ

P

acr (cos = 1)

φ

S

max

Made in Italy

DIN V VDE V 0126-1-1

PROTECTIVE CLASS: I

A4

1:1

1/1

AA

A.Statuti

A.Butini

29/05/2015

G.Fiesoli

Pantone

Process Cyan C

Process Yellow C

LABEL MATERIAL:

3M type 7331 (UL R/C, PGJI2)

INKS:

Refer to UL File MH16411

LABEL CONTENT:

Fixed as shown in the picture

SIZE:

63 mm (height) x 90 mm (width)

29/05/2015

29/05/2015

29/05/2015

C.Granci

All

material

used

and finished product, must meet the requirements of the current RoHS

recti

i

ve 2002/95/EC.

Title

Issued

Modified

D

D

esign approved

Elec. Eng. approved

Mfg. approved

Size

Scale

Dim. in mm

Sheet

Drawing No.

Revision

© Copyright 2014 Power-One Italy Spa. All rights reserved. Reproduction, use or disclosure to third parties without express written authority is strictly forbidden.

Regulatory Label of UNO-3.0-TL-OUTD

UNO LOW COST (V1N)

XLP.V1N04.0AL

MODEL:

UNO-3.0-TL-OUTD

IP65

5 minutes

-25 to + 60 °C

-13 to +140 °F

INVERTER

SOLAR

www.abb.com/solar

600 V

80 - 580 V

16 A

200 - 500 V

20 A

230 V 1Ø

50 Hz

2700 W @ 45 °C amb.

3000 W @ 45 °C amb.

15 A

3000 VA

V

dc max

I

dc max

V

dc MPP

V

dc, Full Power

I

sc max

V

acr

f

r

I

ac max

P

acr (cos = ± 0.9)

φ

P

acr (cos = 1)

φ

S

max

Made in Italy

DIN V VDE V 0126-1-1

PROTECTIVE CLASS: I

A4

1:1

1/1

AA

A.Statuti

A.Butini

29/05/2015

G.Fiesoli

Pantone

Process Cyan C

Process Yellow C

LABEL MATERIAL:

3M type 7331 (UL R/C, PGJI2)

INKS:

Refer to UL File MH16411

LABEL CONTENT:

Fixed as shown in the picture

SIZE:

63 mm (height) x 90 mm (width)

29/05/2015

29/05/2015

29/05/2015

C.Granci

All

material

used

and finished product, must meet the requirements of the current RoHS

recti

i

ve 2002/95/EC.

Title

Issued

Modified

D

D

esign approved

Elec. Eng. approved

Mfg. approved

Size

Scale

Dim. in mm

Sheet

Drawing No.

Revision

© Copyright 2014 Power-One Italy Spa. All rights reserved. Reproduction, use or disclosure to third parties without express written authority is strictly forbidden.

Regulatory Label of UNO-3.6-TL-OUTD

UNO LOW COST (V1N)

XLP.V1N06.0AL

MODEL:

UNO-3.6-TL-OUTD

IP65

5 minutes

-25 to + 60 °C

-13 to +140 °F

INVERTER

SOLAR

www.abb.com/solar

850 V

350 - 820 V

11 A

380 - 700 V

15 A

230 V 1Ø

50 Hz

3240 W @ 45 °C amb.

3600 W @ 45 °C amb.

16 A

3600 VA

V

dc max

I

dc max

V

dc MPP

V

dc, Full Power

I

sc max

V

acr

f

r

I

ac max

P

acr (cos = ± 0.9)

φ

P

acr (cos = 1)

φ

S

max

Made in Italy

DIN V VDE V 0126-1-1

PROTECTIVE CLASS: I

A4

1:1

1/1

AA

A.Statuti

A.Butini

29/05/2015

G.Fiesoli

Pantone

Process Cyan C

Process Yellow C

LABEL MATERIAL:

3M type 7331 (UL R/C, PGJI2)

INKS:

Refer to UL File MH16411

LABEL CONTENT:

Fixed as shown in the picture

SIZE:

63 mm (height) x 90 mm (width)

29/05/2015

29/05/2015

29/05/2015

C.Granci

All

material

used

and finished product, must meet the requirements of the current RoHS

recti

i

ve 2002/95/EC.

Title

Issued

Modified

D

D

esign approved

Elec. Eng. approved

Mfg. approved

Size

Scale

Dim. in mm

Sheet

Drawing No.

Revision

© Copyright 2014 Power-One Italy Spa. All rights reserved. Reproduction, use or disclosure to third parties without express written authority is strictly forbidden.

Regulatory Label of UNO-4.2-TL-OUTD

UNO LOW COST (V1N)

XLP.V1N08.0AL

MODEL:

UNO-4.2-TL-OUTD

IP65

5 minutes

-25 to + 60 °C

-13 to +140 °F

INVERTER

SOLAR

www.abb.com/solar

850 V

350 - 820 V

12.5 A

380 - 700 V

15 A

230 V 1Ø

50 Hz

3780 W @ 45 °C amb.

4200 W @ 45 °C amb.

20 A

4200 VA

V

dc max

I

dc max

V

dc MPP

V

dc, Full Power

I

sc max

V

acr

f

r

I

ac max

P

acr (cos = ± 0.9)

φ

P

acr (cos = 1)

φ

S

max

Made in Italy

DIN V VDE V 0126-1-1

PROTECTIVE CLASS: I

The labels on the equipment must absolutely NOT be removed, damaged, dirtied, hidden, etc.

If the service password is requested, the field to be used is the serial number -SN: YYWWSSSSSS

In the manual and/or in some cases on the equipment, the danger or hazard zones are indicated with signs, labels, symbols or icons.

Obligation to consult

manual

General warning - Important

safety information

Hazardous voltage

Hot surfaces

IP65

Protection rating of

equipment

Temperature range

Without insulation tran-

sformer

Direct and alternating

currents, respectively

Positive pole and negative

pole of the input voltage

(DC)

Obligation to use safety

clothing and/or personal

protection

equipment

Point of connection for

grounding protection.

Stored energy discharge

time

10

01

Inverter model

02

Inverter Part Number

03

Inverter Serial Number

04

Week/Year of manufacture

UNO-X.X-TL-OUTD-Y

P/N:PPPPPPPPPPP

WO:XXXXXXX

SO:SXXXXXXXX Q1

SN:YYWWSSSSSS WK:WWYY

01

02

04

03

The inverter models to which this installation guide refers are available in four power ratings: 2.0 kW, 3.0 kW, 3.6 kW and 4.2 kW.

Two types are available for each model: standard or with DC disconnect switch (Version -S).

Main components

01

Bracket

02

Locking screws

03

Heat sink

04

Anti-condensation valve

05

Front cover

06

LED panel

07

Display

08

Keyboard

09

DC input connectors

10

AC output connector

12

SD Card slot

14

RS485 connector

16

DC disconnect switch

18

Stand-alone board (optional)

19

External ground connection

20

Service cable glands

Available components

Quantity

Bracket for wall mounting

1

Plug, screw and washer for wall

mounting

2 + 2 + 2

M5x10 screw and M5 washer to lock

bracket

2 + 2

M5x10 screw and M5 contact washer

for external ground connection

1 + 2

Two-hole gasket for M20 signal cable

gland and TGM58 cover

1 + 1

Available components

Quantity

Securely sealed connection to

connect AC cable

1

Securely sealed connection to con-

nect RS485 serial line cable

1

TORX TX25 L-key

1

In additio

n to what

is explain

ed in this

guide, th

e safety a

nd installa

tion inform

ation pro

vided in th

e installat

ion manu

al must be

read and

followed

.

The techn

ical docu

mentation

and the in

terface an

d manage

ment softw

are for th

e product

are availa

ble at the

website.

XXXXXXX

XXXX

XXXXXXXX

XXXXXXX

XXXX

XXXXXXXX

ABB solar

inverters

Technical documentation

1

Transportation and handling

Transport of the equipment, especially by road, must be carried out using suitable ways and means in order

to protect the components from violent shocks, humidity, vibration, etc.

Lifting

The means used for lifting must be suitable to bear the weight of the equipment.

Unpacking and checking

The components of the packaging must be removed and disposed of in accordance with the regulations in

force in the country of installation.

When you open the package, check that the equipment is undamaged and make sure all the components

are present.

If any defects or damages are detected, please stop operating, contact the carrier and also promptly inform

the ABB Service Department.

Weight of the modules of the equipment

Model

Weight

UNO-2.0/3.0-TL-OUTD

UNO-2.0/3.0-TL-OUTD-S

UNO-3.6/4.2-TL-OUTD

UNO-3.6/4.2-TL-OUTD-S

12 Kg

Environmental checks

-Consult the technical data to check the environmental conditions to be observed

-Installation of the unit in a location exposed to direct sunlight must be avoided (otherwise the warranty

will be cancelled) as it may cause:

1. power limitation phenomena in the inverter (with a resulting decreased energy production by the

system)

2. premature wear of the electrical/electromechanical components

3. premature wear of the mechanical components (gaskets) and of the user interface (display)

-Do not install in small closed rooms where air cannot circulate freely

-

Always ensure that the flow of air around the inverter is not blocked so as to prevent overheating.

-

Do not install in places where gases or flammable substances may be present

-Do not install in rooms where people live or where the prolonged presence of people or animals is ex-

pected, because of the noise level that the inverter produces during operation. The level of the sound

emission is heavily influenced by where the inverter is installed (for example: the type of surface

around the inverter, the general properties of the room, etc.) and the quality of the electricity supply.

Installations above 2000 metres

On account of the rarefaction of the air (at high altitudes), particular conditions may occur:

-

Less efficient cooling and therefore a greater likelihood of the device going into derating because of

high internal temperatures

-Reduction in the dielectric resistance of the air that, in the presence of high operating voltages (DC

input), can cause arcing (electrical discharges) that may reach the point of damaging the inverter

All installations at altitudes of over 2000 metres must be assessed case by case with the ABB

Service department.

Installation site

-Install on a wall or strong structure capable of bearing the weight of the equipment

-Install in safe, easy to reach places.

-If possible, install at eye-level so that the display can be seen easily

-Install at a height that takes account of the weight of the equipment

-Install vertically with a maximum inclination of 5° (forward or backward)

-

Choose a place that enables sufficient space to be left around the unit to enable

easy installation and removal of the object from the assembly surface; respect the

minimum distances indicated

-In the case of multiple installation position the inverters alongside each other;

if the space available does not allow this arrangement, position the inverters in

a staggered arrangement as shown in the figure so that heat dissipation is not

affected by other inverters

Final installation of the inverter must not compromise access to any discon

-

nection devices that may be located externally.

Please refer to the warranty terms and conditions available on the website

and evaluate any possible exclusions due to improper installation.

15

cm

20

cm

10cm

10cm

Wall mounting

During installation do not place the inverter with the front cover

05

facing towards the ground.

- Position the bracket

01

so that it is perfectly level on the wall and use it as a template for

drilling.

- Make the 2 holes necessary, using a drill with a 10 mm. diameter bit. The depth of the holes

must be around 70 mm.

- Secure the bracket to the wall with the two 10 mm wall plugs supplied with it.

- Attach the inverter by inserting the two tabs on the bracket

01

into the 2 slots on the inverter

(figures A1 and A2).

- Secure the inverter to the bracket by screwing the lock screws

02

on both sides of the

inverter (figure A3).

- If necessary unscrew the 8 screws and open the front cover

05

to make all accessory

connections.

Do not open the inverter in the case of rain, snow or a high level of humidity

(>95%)

• Once the connections have been made proceed to closing the cover by tightening the 8

screws on the front, adhering to the tightening sequence and torque (2.5Nm).

POW

ER

ALARM

GFI

UP

ESC

ENTER

DOWN

UNO-2.0/3.0/3.6/4.2-TL-OUTD

UNO-2.0/3.0/3.6/4.2-TL-OUTD-S

03

09

04

03

14

20

19

10

09

04

03

14

16

20

19

10

01

01

02

03

18

14

10

20

06

07

05

08

12

16

09

04

A

A

1

A

2

A

3

Check for correct polarity in the input strings and absence of any leakage to ground in the PV generator.

When exposed to sunlight, the PV panels supply DC direct voltage to the inverter.

The inside of the inverter may only be accessed after the equipment has been disconnected from the grid and from the photovoltaic

generator.

Warning! The inverters referred to in this document are TRANSFORMERLESS. This typology implies the use of insulated photovoltaic

panels (IEC61730 Class A Rating) and the need to keep the photovoltaic generator floating with respect to the ground: no terminal of the

generator must be grounded.

The inverter has a single input channel (MPPT) and is equipped with a pair of quick fit connectors

09

to

connect the PV generator

If the input strings should be connectd in parallel, they must have the same installation conditions

(number of panels in series, type of panels, orientation and inclination).

Comply with the maximum input current relating to the quick fit connectors.

-Refer to the document “String inverter – Product Manual appendix” available at www.abb.com/solarinver-

ters to know the brand and the model of the quick fit connector. Depending on the model of the connector

of the own inverter, it is necessary to use the same model and the respective counterpart (check the

compliant counterpart on the website of the manufacturer or in ABB).

Using corresponding parts that are not compliant with the quick fit connector models on the

inverter could cause serious damage to the unit and lead to invalidation of the warranty.

-Connect the DC input and always check the tightness of the connectors

09