22

A

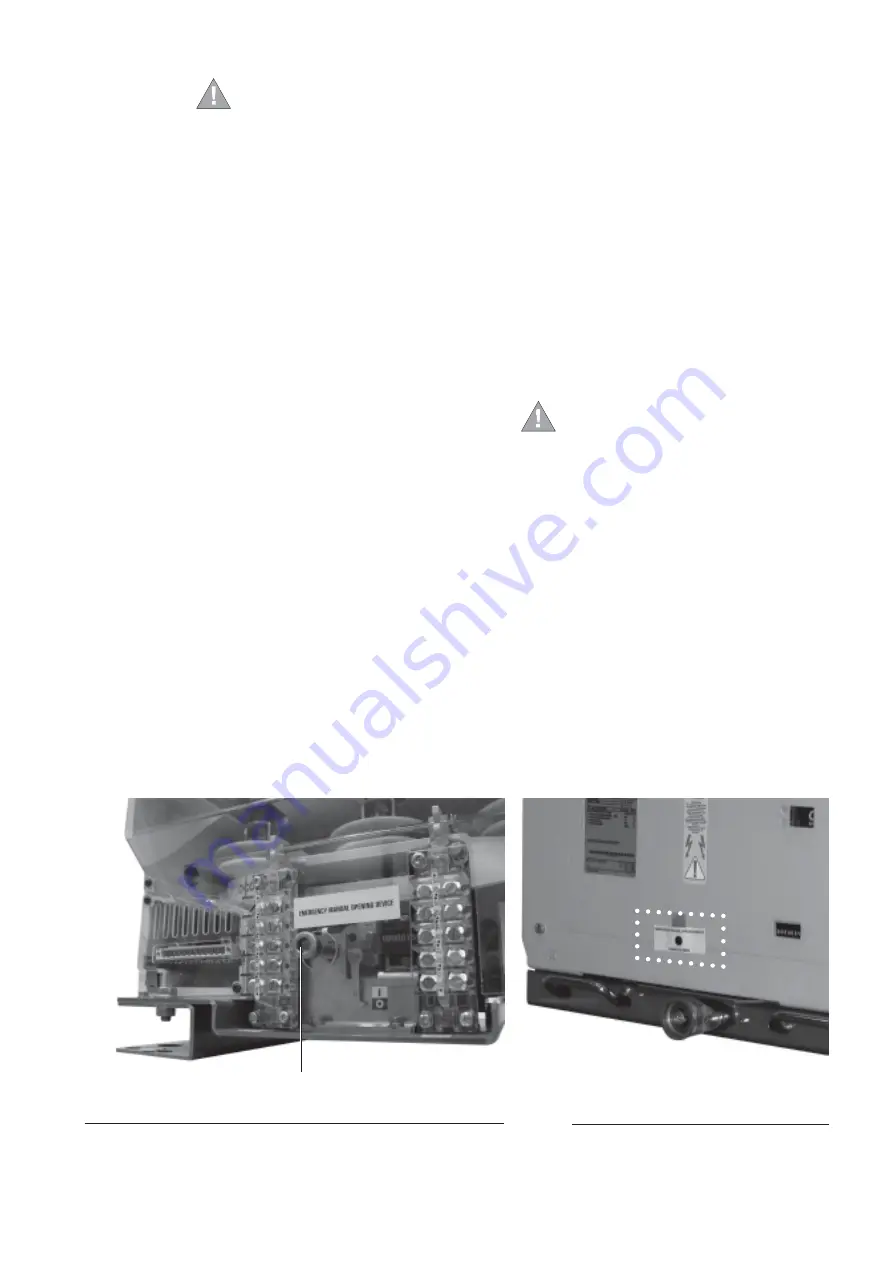

Fig. 10 a

a transmission made of insulating material of

suitable length which allows safe operation. The

transmission device is to be provided by the

customer.

For the withdrawable VSC/P contactors placed

in UniGear ZS1 type switchgear or PowerCube

modules, carry out the emergency operation

with the compartment door closed. To carry out

the operation, work towards the opening on the

compartment door using the special tool pro-

vided, fitted on the end with an 8 mm hexago-

nal spanner. Apply a torque of 5 N with an oper-

ating angle of about 30° clockwise. The point to

operate in is shown by the special plate located

on the contactor shield (see fig. 10b).

For fixed contactors, if the operations

are carried out with the medium volt-

age protection “B” removed, pay great

attention to the moving parts.

For withdrawable contactors, do not

remove the front shield to carry out the

emergency opening operation.

In any case, if auxiliary voltage is

present, take special care not to re-

move the protective shield of the

stored energy capacitor and not to

touch the capacitor itself in any way.

5.8. Emergency opening operation

The contactor is provided with manual

emergency operation which must be

carried out by suitably qualified per-

sonnel with in-depth knowledge of the

apparatus and with voltage to the ap-

paratus compulsorily turned off on the

power supply side.

The following Standards must be

taken into particular consideration

during installation and service:

– IEC60694/DIN VDE 0101

– VDE 0105: Operation of electrical

plants

– DIN VDE 0141: Earthing systems for

electrical installations with rated

voltage higher than 1 kV

– All the accident prevention regula-

tions, in force in the relative coun-

tries.

To manually open the contactor, it is necessary

to work on operating part A, consisting of a 17

mm hexagonal-head bolt, working clockwise

with a torque of about 5 Nm and at an angle of

about 30° (see fig. 10a).

If the contactor (in the fixed version) is placed

inside the switchgear, it is necessary to provide

Fig. 10 b

Summary of Contents for V-Contact VSC 12

Page 1: ...V Contact VSC Installation and service instructions 7 2 12 kV 400 A ...

Page 2: ...1 ...

Page 35: ...33 50 50 49 49 Fig 18c Fig 18b ...

Page 39: ...1 ...