29

Operation to be carried out

Visual inspection of the insulating parts. The insulating parts must

be free of any accumulation of dust, humidity, dirt (clean), cracks,

traces of surface discharges or damage.

Visual inspection of the structure and mechanisms. The components

must be free of any deformation, accumulation of dust, dirt or dam-

age. The screws, nuts and bolts must be correctly tightened. Avoid

touching the ceramic surface.

Check that the interrupter is free of accumulation of dust, dirt (clean),

cracks (replace), traces of surface discharges or damage.

Carry out a voltage test with the contacts open at 15 kV - 50 Hz for

one minute. If there is a discharge during the test, the interrupter

must be replaced because this type of phenomenon corresponds to

deterioration in the degree of vacuum. In case of need, contact ABB

Service.

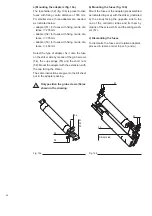

Refer to fig. 16. The contact material vaporises from the surfaces

during each interruption and condenses elsewhere inside the vacuum

interrupter. This is a normal process, and is foreseen by the overrun,

or by the wear tolerance.

As the contacts wear, the overrun distance “M” decreases. When

distance “M”, of any pole, goes below 0.5 mm with the contactor in

the closed position, all the sub-assemblies must be replaced.

Use a fork-shaped gauge 0.5 mm thick to carry out this measure-

ment.

Caution! Never attempt to adjust the nuts of the vacuum inter-

rupters for any reason whatsoever.

The overrun distance must be checked, but not adjusted.

Check correct operation and the signals.Check that there are no burnt

or worn contacts (replace).

Check whether any cabling straps are loose or broken and check

connection tightness.Examine all the wire or cable connections to

make sure that none of them are loose and that there is no over-

heating.

The isolating contacts must be free of any deformation or erosion.

Lubricate the contact elements with 5RX Moly type grease.

Item to be

inspected

1 Insulating parts.

2 Structure.

3 Interrupter.

4 Interrupter contacts.

5 Auxiliary contacts.

6 Auxiliary circuit conduc-

tors.

7 Visual inspection of the iso-

lating contacts (withdrawa-

ble contactors)

Interval

1 year or

50,000 operations.

1 year or

50,000 operations.

1 year or

50,000 operations.

In case of accidental

impacts.

1 year or

50,000 interruptions

at the rated current.

1 year or

50,000 operations.

1 year or

50,000 operations.

5 years or

5.000 operations.

TABLE 4

Operation to be carried out

Carry out five mechanical closing and opening operations. The con-

tactor must operate regularly without stopping in intermediate posi-

tions.

Check integrity of the springs.

Check tightness: M8 bolt = 19 Nm; M10 bolt = 33 Nm.

Check there are no traces of overheating or oxidation.

Check tightness of the connections.

See par. 6.1.

Check that the signals are correct.

Item to be

serviced

1 Contactor.

2 Contactor springs.

3 Power connections.

4 Earthing contact

(fixed contactors).

5 Insulation resistance.

6 Racked-in/isolated aux-

iliary contacts in the

truck.

Interval

2 years or

100,000 operations.

2 years or

100,000 operations.

2 years or

100,000 operations.

2 years or

100,000 operations.

2 years or

100,000 operations.

2 years or

100,000 operations.

7.3. Servicing

Carry out the checks described below.

Furthermore the following is

recommended:

– replacement of the inter-

rupters after 250,000 op-

erations;

– replacement of the auxil-

iary contacts after 300,000

operations.

Summary of Contents for V-Contact VSC Series

Page 1: ...V Contact VSC Installation and service instructions 7 2 12 kV 400 A ...

Page 2: ...1 ...

Page 35: ...33 50 50 49 49 Fig 18c Fig 18b ...

Page 39: ...1 ...