10 CI/EDP300-EN Rev. A |

D500

Change from one to two columns

3

Mounting

CAUTION – Minor injuries

Incorrect parameter valves can cause the valve to

move unexpectedly. This can lead to process

failures and result in injuries.

Before recommissioning a positioner that was

previously in use at another location, always reset

the device to its factory settings. Never start Auto

Adjust before restoring the factory settings.

3.1

Operating conditions at installation site

IMPORTANT (NOTE)

Before installation, check whether the positioner

meets the control and safety requirements for the

installation location (actuator or valve).

See the "Specifications” section on the data

sheet.

3.2

Mechanical mounting

3.2.1

General information

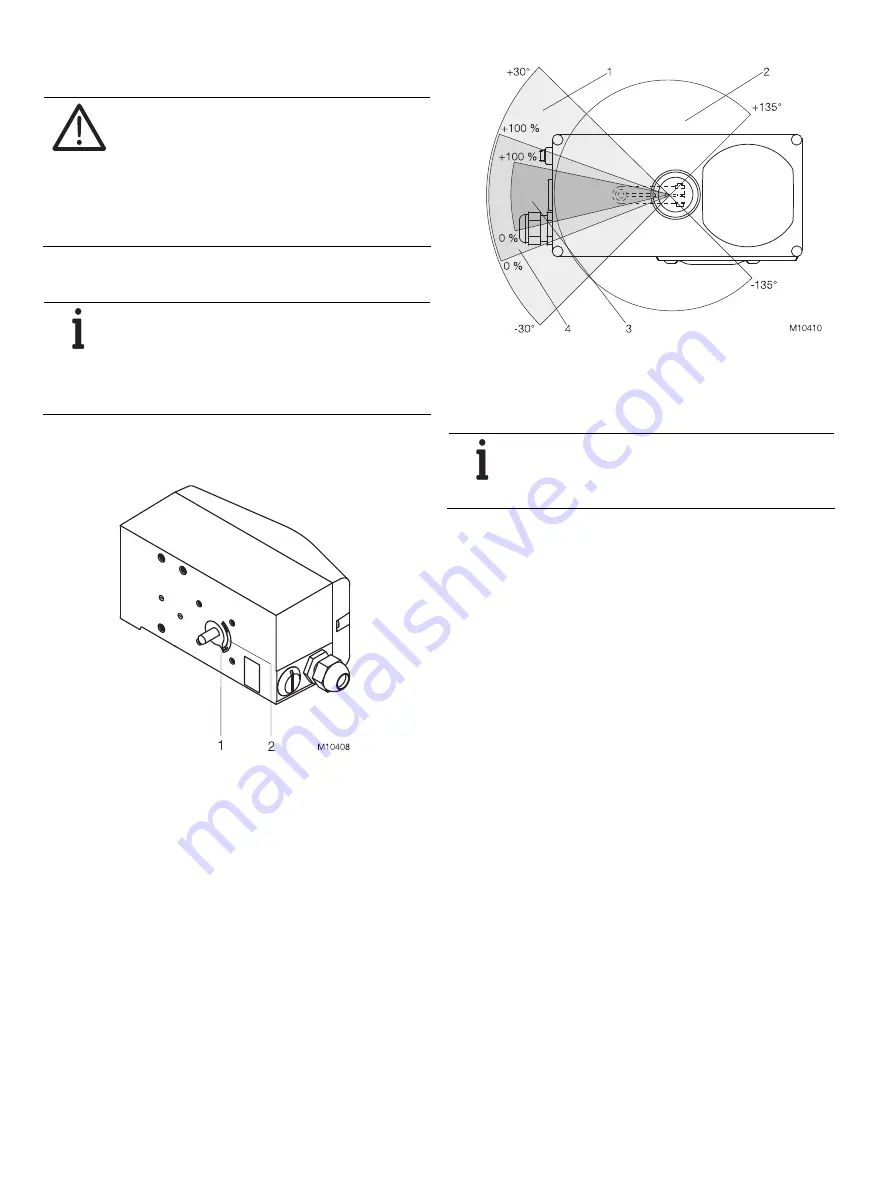

Fig. 2:

Working range

The arrow (1) on the positioner feedback shaft (position

feedback point) must move between the arrow marks (2).

Fig. 3:

Sensor and operating ranges of the positioner

1 Sensor range for linear actuators |

2 Sensor range for part-turn actuators |

3 Working range for linear actuators |

4 Working range for part-turn actuators

IMPORTANT (NOTE)

During installation make sure that the actuator

travel or rotation angle for position feedback is

implemented correctly.

The maximum rotation angle for position feedback is 60° when

installed on linear actuators and 270° on part-turn actuators.

The minimum rotation angle is always 25°.