D500

| CI/EDP300-EN Rev. A 11

3.2.2

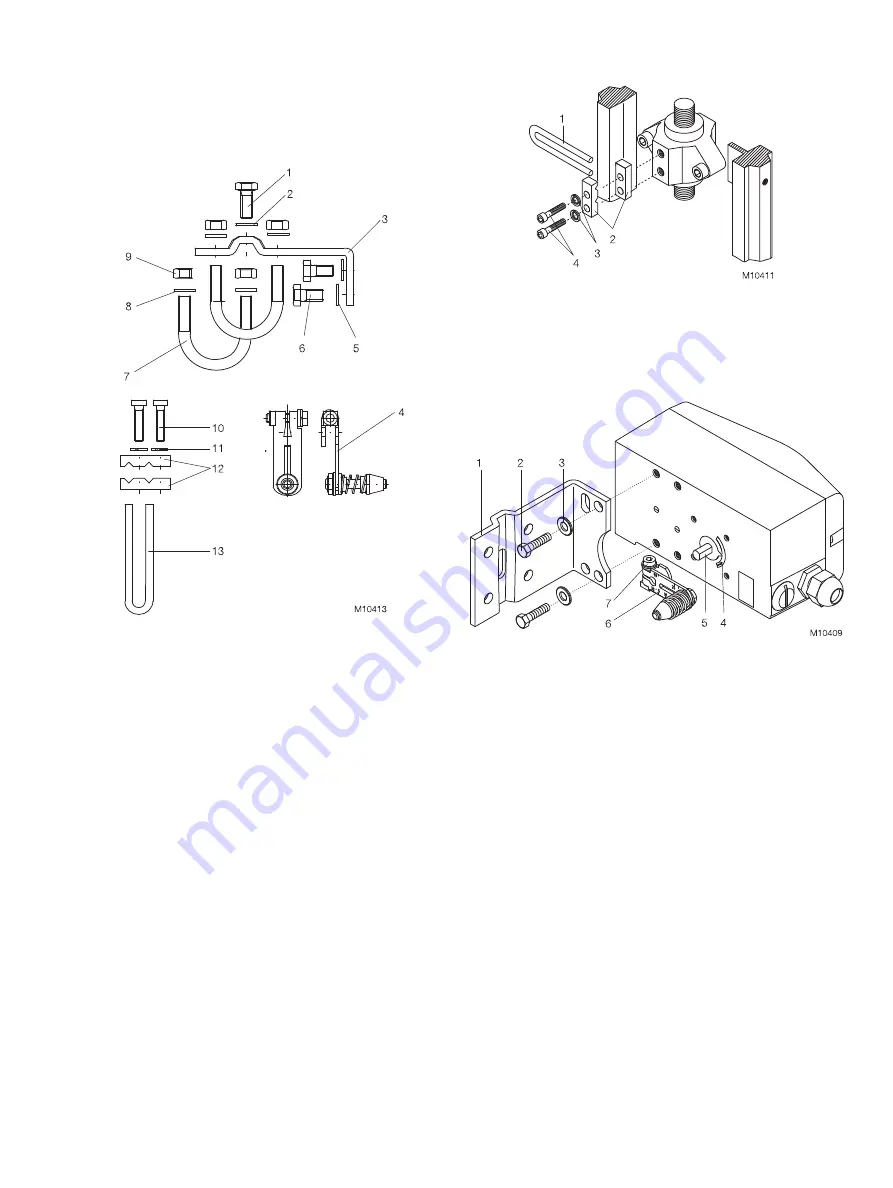

Mounting on linear actuators

For mounting on a linear actuator in accordance with DIN /

IEC 534 (lateral mounting as per NAMUR), the following

mounting kit is available:

Fig. 4

1 Screw | 2 Shim | 3 Mount bracket |

4 Lever with follower pin (for stroke adjustment 10 … 35 mm

(0.39 … 1.38 inch) or 20 … 100 mm (0.79 … 3.94 inch) |

5 Shims | 6 Screws | 7 U-bolts | 8 Shims | 9 Nuts |

10 Screws | 11 Spring washers | 12 Clamp plates |

13 Follower guides

Attaching a follower guide to the actuator

Fig. 5

1.

Tighten the screws so that they are hand-tight.

2.

Attach the follower guide (1) and clamp plates (2) with

screws (4) and spring washers (3) to the actuator stem.

Mounting lever and bracket on positioner

Fig. 6

1.

Attach the lever (6) to the feedback shaft (5) of the

positioner (can only be mounted in one position due to the

cut shape of the feedback shaft).

2.

Using the arrow marks (4), check whether the lever moves

within the operating range (between the arrows).

3.

Tighten the screw (7) on the lever so that it is hand-tight.

4.

Hold the prepared positioner (with the mount bracket (1)

still loose) on the actuator so that the follower pin for the

lever enters the follower guide to determine which tap

holes on the positioner must be used for the mount

bracket.

5.

Secure the mount bracket (1) with screws (2) and shims

(3) using the relevant tap holes on the positioner housing.

Tighten the screws as evenly as possible to ensure

subsequent linearity. Align the mount bracket in the

oblong hole to ensure that the operating range is

symmetrical (lever moves between the arrow marks (4).