18 CI/EDP300-EN Rev. A |

D500

5

Pneumatic connection

hange from one to two columns

IMPORTANT (NOTE)

The positioner must only be supplied with

instrument air that is free of oil, water, and dust (in

the gas exhaust with dried natural gas).

The purity and oil content must meet the

requirements of Class 3 according to DIN/ISO

8573-1.

IMPORTANT (NOTE)

On double-acting drives with spring-return

mechanism, a chamber pressure that significantly

exceeds the supply pressure value can be

generated during operation by the springs in the

chamber opposite the springs.

NOTICE – Potential damage to parts

Contamination on the air pipe and positioner can

damage components.

Dust, splinters, and any other particles of dirt must

be blown off the pipe before it is connected.

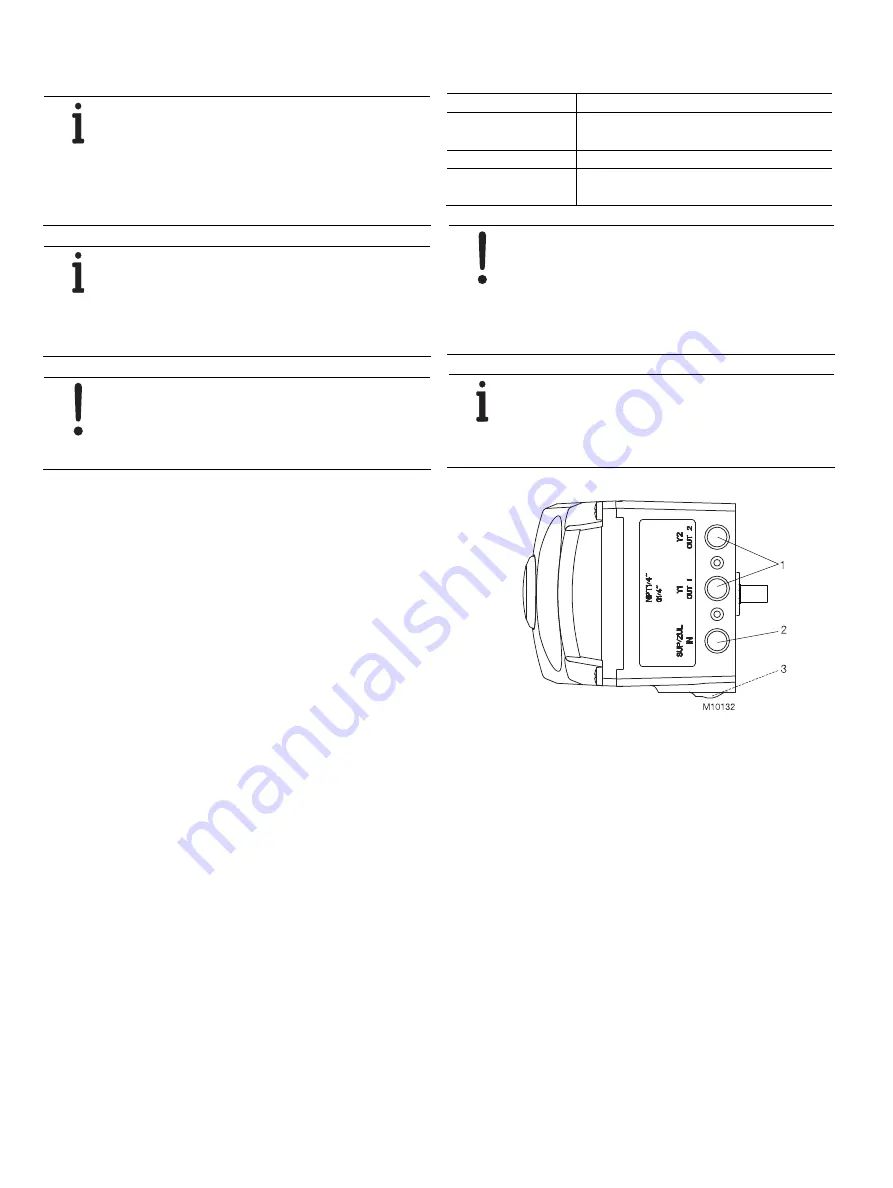

All pneumatic piping connections are located on the right-

hand side of the positioner. G1/4 or 1/4 18 NPT tap holes are

provided for the pneumatic connections. The positioner is

labeled according to the tap holes available.

We recommend that you use a line with dimensions of 12 x

1.75 mm. The level of supply air pressure required to apply the

actuating force must be adjusted in line with the output

pressure in the actuator.

The working range for the positioner is between 1.4 ... 10 bar

(20 ... 145 psi).

Connect the connections according to their labeling:

Designation

Pipe connection

SUP / ZUL IN

Air supply, pressure 1.4 ... 10 bar

(20 ... 145 psi)

Y1 / OUT1

Actuating pressure for actuator

Y2 / OUT2

Actuating pressure for actuator (2nd connection

with double-acting actuator)

NOTICE – Potential damage to parts

Pressure above 10 bar (145 psi) can damage the

positioner or actuator.

Provisions must be made (e.g., use of a pressure

regulator) to ensure that the pressure does not

rise above 10 bar (145 psi), even in the event of a

fault.

IMPORTANT (NOTE)

On double-acting drives with spring-return

mechanism, a stop valve must be fitted in the

supply line. Otherwise, the Auto Adjust function is

aborted and the valve cannot be regulated.

Fig. 19: Pneumatic connections

1 Pneumatic outputs | 2 Supply air |

3 Filter screw (on underside of housing)