24

Circuit-breaker racking-in/-out must be carried out

gradually to avoid shocks which may deform the

mechanical interlocks and the limit switches.

The torque normally required to carry out rack-

ing-in and racking-out is

£

25 Nm.

This value must not be exceeded. If operations

are prevented or difficult, do not force them and

check that the operating sequence is correct.

Note

To complete the racking-in/out operation, about

20 rotations of the lever are required for circuit-

breakers up to 17.5 kV, and about 30 rotations

for 24 kV circuit-breakers.

When the circuit-breaker has reached the isolated

for test/isolated position, it can be considered to

be racked into the switchgear and, at the same

time, earthed by means of the truck wheels.

Withdrawable circuit-breakers of the same

version, and therefore of the same dimensions,

are interchangeable.

However, when different fitting of electrical

accessories is foreseen, for example, different

coding of the auxiliary circuit plug prevents

incorrect combinations between circuit-breakers

and panels.

The racking-in/-out operations must

always be carried out with the circuit-

breaker open.

7.5.1. Circuit-breakers with motor-driven

withdrawable truck (on request)

Test the motor-driven truck in the same way as

a truck with manual racking-in:

– turn off the truck motor circuit power supply to

lock it electrically;

– turn the crank handle (1) (fig. 9) to the desired

position.

Note

When the moving part moves, it makes the motor

turn, which, acting like a generator, can cause a

reverse voltage at the connection terminals.

7.3. Preliminary operations

– Clean the insulating parts with clean dry cloths.

– Check that the top and bottom terminals are

clean and free of any deformation caused by

shocks received during transport or storage.

7.4. Installation of fixed circuit-breakers

The circuit-breaker can be mounted directly on

supporting frames to be provided by the cus-

tomer, or on a special supporting truck (avail-

able on request).

The circuit-breaker, with supporting truck, must

be suitably fixed to the floor of its own

compartment by the customer.

The floor surface in correspondence with the truck

wheels must be carefully levelled.

A minimum degree of protection (IP2X) must be

guaranteed from the front towards live parts.

7.4.1. Mounting the circuit-breaker on trucks

constructed by other manufacturers

VD4 circuit-breakers which are not installed on

ABB trucks, but on trucks constructed by the

customer must be fitted with one or two additional

auxiliary contacts (activated by the mechanical

lock and by the circuit-breaker trip device)

entrusted with the function of interrupting the

shunt closing release circuit release (-MC).

In ABB trucks, this function is carried out by the

auxiliary contacts -BT1 and -BT2 which cut of

the release power supply during and before

activation of the mechanical lock of the screw

device for racking the truck in. This means the

shunt closing release power supply can only be

applied after activation of the mechanical lock.

In this way there is the certainty that no electrical

impulse can activate the shunt closing release

with the circuit-breaker in the intermediate

position.

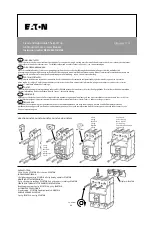

7.5. Installation of withdrawable circuit-

breakers

The withdrawable circuit-breakers are preset for

use in UniGear type ZS1 and UniSafe switchgear.

For racking-in/racking-out of the switchgear, fully

insert the lever (1) (fig. 9) in the appropriate seat

(2) and work it clockwise for racking-in, and anti-

clockwise for racking-out, until the limit switch

positions are reached.

All manuals and user guides at all-guides.com

all-guides.com