26

7.6. Power circuit connections of fixed

circuit-breakers

7.6.1. General recommendations

– Select the cross-section of the conductors

according to the service current and the short-

circuit current of the installation.

– Prepare special pole insulators, near the ter-

minals of the fixed circuit-breaker or of the

enclosure, sized according to the electrody-

namic forces deriving from the short-circuit

current of the installation.

7.6.2. Assembly of the connections

– Check that the contact surfaces of the con-

nections are flat, and are free of any burrs,

traces of oxidation or deformation caused by

drilling or impacts received.

– According to the conductor material and the

surface treatment used, carry out the opera-

tions indicated in table T1 on the contact sur-

face of the conductor.

Bare copper

– Clean with a fine file or

emery cloth.

– Tighten fully and cover the

contact surfaces with 5RX

Moly type grease.

Copper or silver-plated aluminium

– Clean with a rough dry cloth.

– Only in the case of obstinate traces of

oxidation, clean with a very fine grain

emery cloth taking care not to remove

the surface layer.

– If necessary, restore the surface treat-

ment.

Bare aluminium

– Clean with a metal brush or emery cloth

– Cover the contact surfaces again im-

mediately with neutral grease.

– Insert the copper-aluminium bimetal with

surfaces shined (copper side in contact

with the terminal; aluminium side in con-

tact with the connection) between the

aluminium connection and the copper

terminal.

Assembly procedure

– Put the connections in contact with the circuit-

breaker terminals taking care to avoid mechani-

cal stresses (traction / compression) on, for

example, the conducting busbars on the ter-

minals.

– Interpose a spring washer and a flat washer

between the head of the bolt and the connec-

tion.

– It is advisable to use bolts according to DIN

class 8.8 Standards, also referring to what is

indicated in table T2.

– In the case of cable connections, strictly fol-

low the manufacturer’s instructions to make the

terminals.

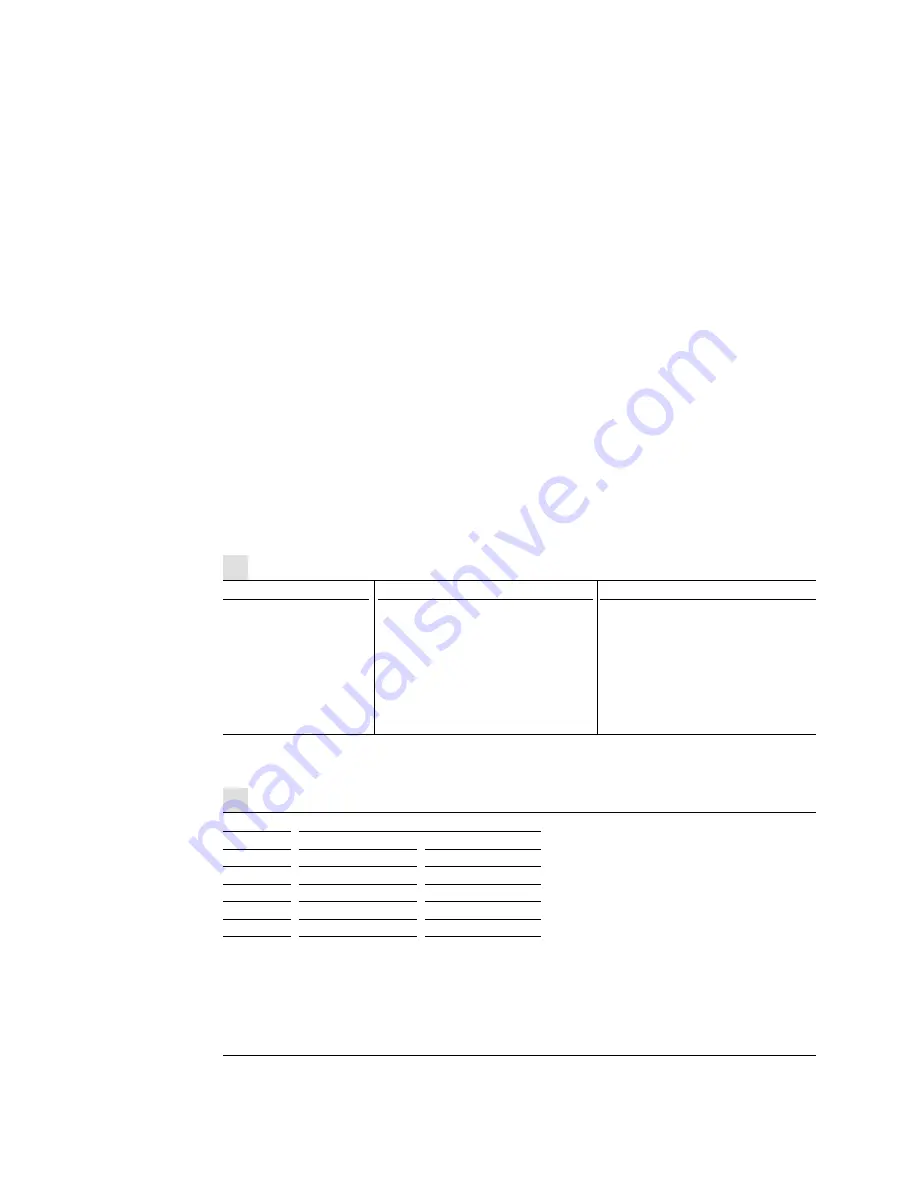

T2

Bolt

M6

M8

M10

M12

M16

Without lubricant

10.5 Nm

26 Nm

50 Nm

86 Nm

200 Nm

Recommended tightening torque (1)

With lubricant (2)

4.5 Nm

10 Nm

20 Nm

40 Nm

80 Nm

(1) The nominal tightening torque is based on a fric-

tion coefficient of the thread of 0.14 (distributed

value the thread is subjected to which, in some

cases, is not negligible).

The nominal tightening torque with lubricant is

according to the DIN 43673 Standards.

(2) Oil or grease. The thread and surfaces in con-

tact with the lubricated heads.

Take into account the deviations from the general

Standards table (for example, for systems in con-

tact or terminals) as foreseen in the specific techni-

cal documentation.

The thread and surfaces in contact with the heads

of bolts must be slightly oiled or greased, so as to

obtain correct nominal tightening torque.

T1

All manuals and user guides at all-guides.com