41

8

19

18

(4)/

4.2

11

12

13

14

3.1

4 1 5

48 1 3.1

48.2

48.3

48.1

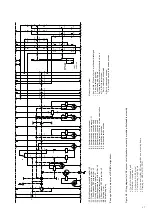

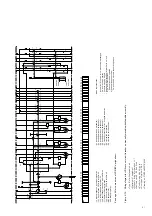

Figure 7/1: Manual operation and mechanical indicators

of a withdrawable breaker part, withdrawable

circuit-breaker part in test/disconnected position

Note:

Test switching of the circuit-breaker without primary

voltage can be carried out with the withdrawable part in

the test position (with the control wiring plug fitted).

3.1

Sliding handle, connected to the catch in

the withdrawable part base frame

(4)

Spindle mechanism

4.2

Square spigot

8

Control wiring plug connection

11

Mechanical ON push-button

12

Mechanical OFF push-button

13

Mechanical position indicator

14

Mechanical operating cycle counter

18

Charging condition indicator

19

Charging lever

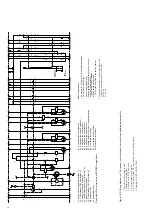

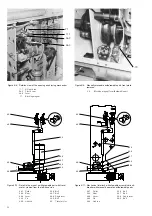

Figure 7/2: Movement of the withdrawable breaker part between

the test/disconnected position and the service position,

clockwise up to the stop for the service position and

anti-clockwise for the test/disconnected position

1

Withdrawable circuit-breaker part

4

Spindle mechanism

5

Hand crank

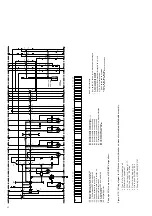

Figure 7/4: Service truck engaged with the panel. Withdrawable

circuit-breaker part released for removal by moving the

sliding handles inwards

1

Withdrawable circuit-breaker part

3.1

Sliding handle

48

Service truck (not included in supply)

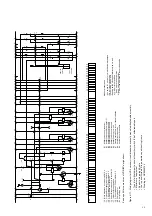

Figure 7/3:

Approaching the panel and positioning the service

truck with the guide pins of the adjustable height bench

top at the correct height for the catch to engage

48.1

Height adjuster

48.2

Guide pin

48.3

Catch