VMS user manual

10

Maintenance

Maintenance intervals:

The maintenance intervals depend on the intensity of use of the switchgear

installed in the switchboard and can be either preventive or repair work, but should

always be in accordance with local regulations and standards (i.e. NEN3140).

Attention:

Observe all relevant operating instructions of the electrical components as well as

local requirements, regulations and standards (i.e. NEN3140).

Inspection interval:

A visual inspection as well as a control of mechanical functions (e.g. interlocks etc.)

of the assembly should be done every 4 years as a minimum.

An interval of <= 1 year is recommended.

The following checklist can be applied as a guideline during inspection.

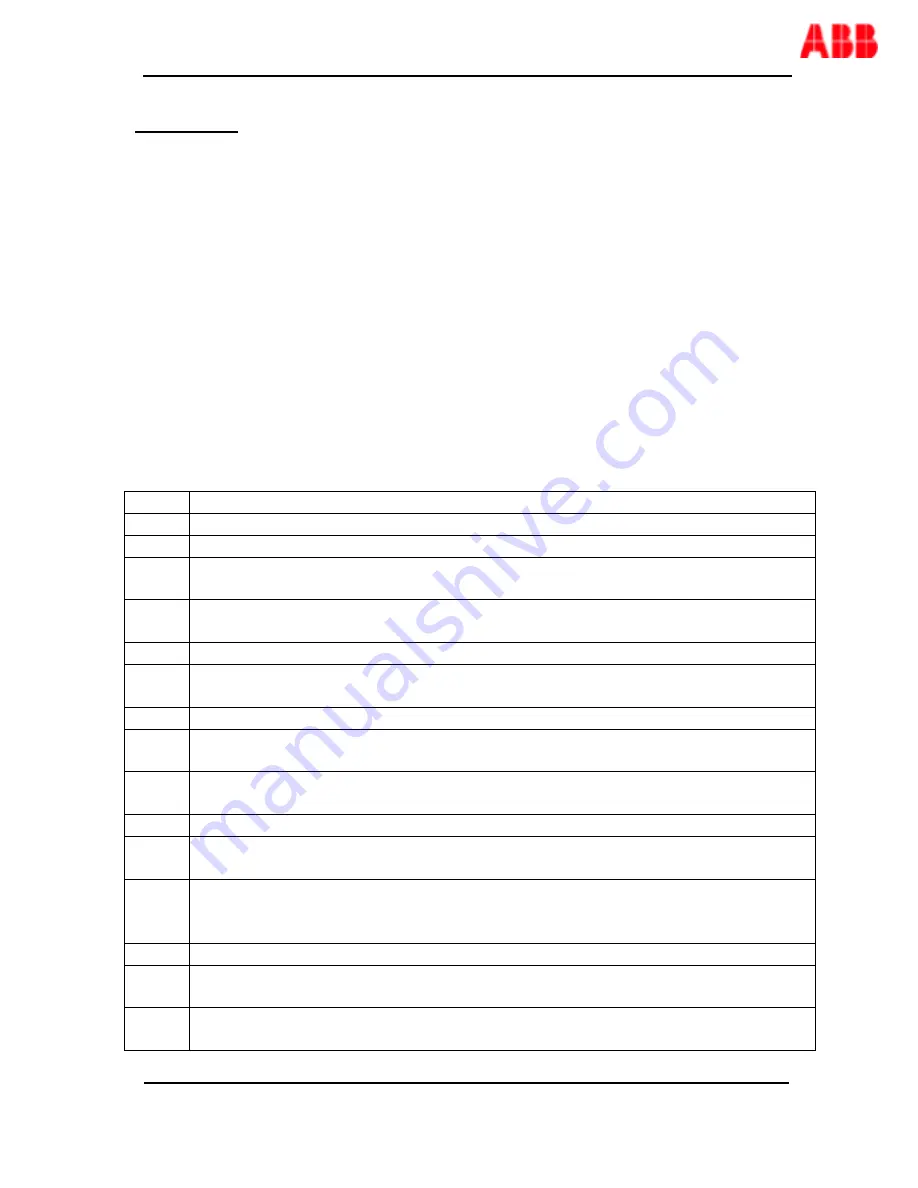

#

Inspection / corrective action

1

inspection of service conditions

2

(visual) inspection of the assembly

3

inspection of the ventilation openings clean ventilation openings / change dust

filters

4

inspection of measures to achieve IP rating,

no ingress of condensation. Unused

gland opening

5

inspection of cables &

glanding’s

6

inspection on the effects of pollution, clean with dry piece of cloth or use

vacuum cleaner / do not use high pressure air!

7

inspection for damages

8

inspection on the effects of corrosion, repair failures on surface / make dry if

necessary

9

inspection of sub-assemblies & electrical components maintenance in

accordance with relevant component manuals

10

inspection of connectors & terminals

11

check correct protection of electrical components & cables, change fuses if

necessary (decoloring, correctly placed)

12

check settings of electrical components (e.g. overload & short circuit protection)

correct settings according the documentation of the electrical component. Test

Residual Current (earth leakage) devices.

13

inspection of plug-in contacts remove old grease, put new grease on

14

inspection of measures against electrical shock (PE conductor, PE connections)

check insulation resistance (earth resistance /dielectric testing).

15

check torque values for electrical connections (see torque values for electrical

connections),

µΩ testing of busbar

system