2104349 rev. AD

Page 3

–7

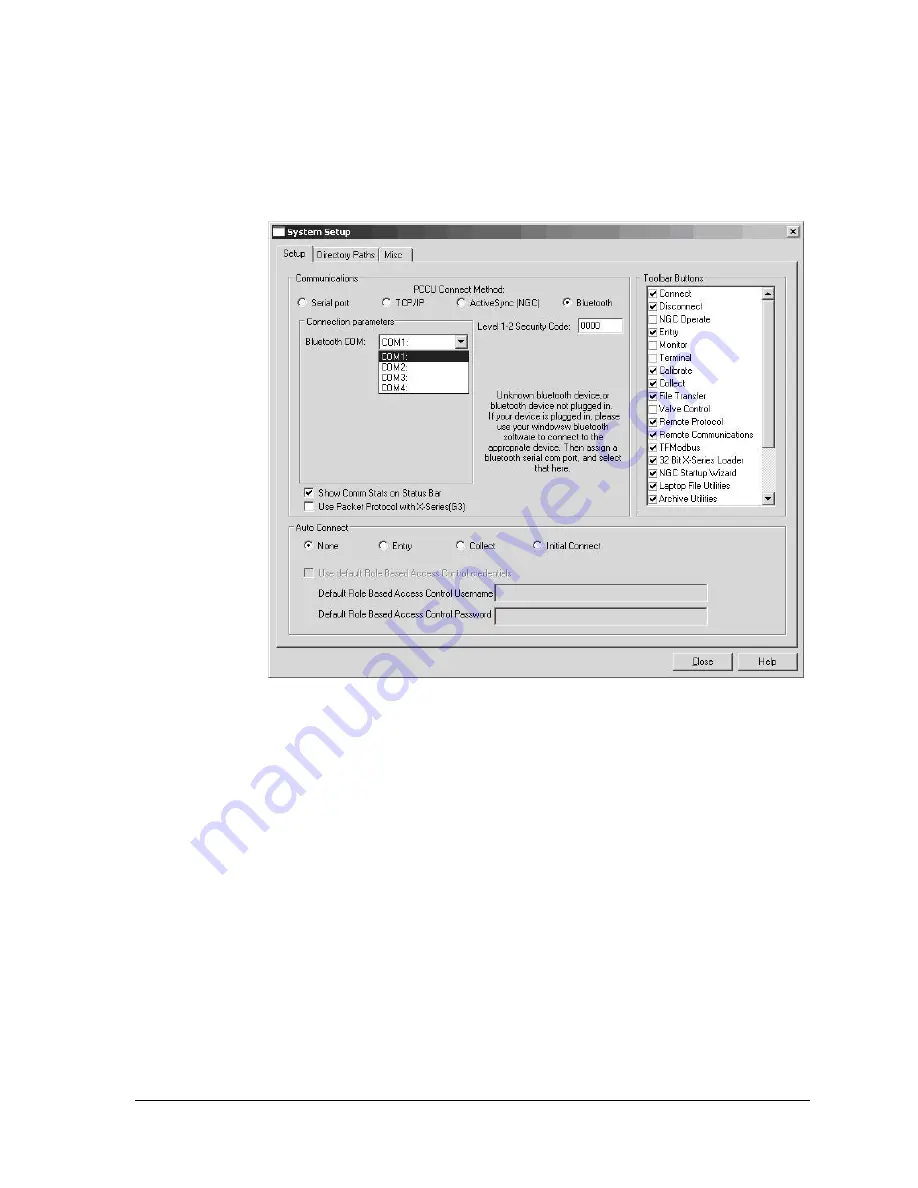

9) It should be noted that if the Bluetooth adapter plugged into the computer is

one that is not supported, the user will receive a different screen in the

System Setup dialog box (see Figure 3

–7). At this point, the user must use

their Windows software that came with the Bluetooth adapter, and set up a

pair/connection to the preferred Totalflow Bluetooth-enabled device.

Figure 3

–7 System Setup dialog box - Bluetooth

10) Once the pair/connection has been made, the user will need to assign a

communication port to it. After this is accomplished, the user can set the

com port in the drop-down list provided on the System Setup dialog box.

11) The user will then need to close the System Setup screen, and connect to

PCCU32 to communicate with the device.

3.2.4 Setup of the G4 EX for Ethernet connectivity

To set up the G4 EX for an Ethernet connection, the user must first connect locally

using either the RS-232 or USB cable. Using the local connection allows the user

to setup the device for Ethernet connectivity.

Currently, there are a variety of methods for completing this task. The following

will cover two such methods.

3.2.4.1

Method one

1) Connect locally using either the RS-232 instructions or the USB instructions

covered in the previous section(s).

Summary of Contents for XSeries G4 6200

Page 42: ......

Page 61: ...2104349 rev AD Page 2 19 Figure 2 18 G4 EX to UPS ...

Page 62: ......

Page 130: ......

Page 163: ...2104349 rev AD Page 33 ...