10

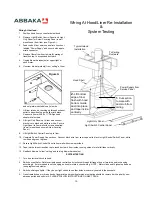

Wiring At the Hood:

1.

Position hood liner on counter below hood.

2.

Remove Light /Switch Control Panel and Light

Only Panel (or Screw Covering Panel in wall

mount hood) from liner (see Figure A).

3.

Feed conduit from service panel into knock out

labeled “Power Supply” and secure with appro-

priate connector.

4.

Remove filters from liner to simplify mating of

transition top to suspended ductwork.

5.

Unplug blower harness(es) at upper right of

each motor.

6.

Unscrew blower plates(s) from “ceiling” of liner

and set plate-mounted blower(s) aside.

7.

Lift liner into hood, reaching up through exhaust

outlet to transition top, guide liner into place.

Re-secure liner with # 8 x ½" Phillips head

sheet metal screws.

8.

Lift Light Only Panel up to liner and connect

black wire to black and white to white. Secure

Light Panel to liner wall with screws supplied.

(In wall mount hood secure Screw Covering

Panel.)

9.

Lift Light/Switch Control Panel up to liner.

10. Complete Power Supply Connections. Connect black wire from service panel to black in Light/Control Switch Panel, white

to white and green to green.

11. Secure Light/Switch Control Panel to liner wall with screws provided.

12. Tape joint between transition top to round ductwork from inside, running strips of metal foil tape vertically.

13. Reattach blowers to liner “ceiling” and re-plug blower harness(es).

SYSTEM TESTING

1.

Turn on electrical circuit to hood.

2.

Switch on ventilator. Rotate variable speed control knob clockwise through full range to see if motor speed is changing

accordingly. If motor speed is not changing as knob is rotated, check wiring. NOTE: Motor clicks on at highest speed and

runs progressively slower.

3.

Switch on halogen lights. If they do not light, check to see that bulbs are securely seated in their sockets.

4.

On untreated copper or brass hoods, fingerprints and resulting tarnish or oxidation should be removed with a quality, non-

abrasive polish and soft cloth - PLEASE FOLLOW INSTRUCTIONS ON NEXT PAGE.

Wiring At Hood/Liner Re-Installation

&

System Testing

Hood Shell

Typical Island

Installation

To Ceiling

Ductwork

2.

Lift bottom

edge of liner

flush with hood

bottom. Guide

duct into place

and tape inside.

vertically

1.

Cut section

to mate with

duct stub from

ceiling

B

C

A

Light /Switch Control Panel

Light Only Panel

Power Supply from

Service Panel

Figure A