TM402-200 OPERATOR’S MANUAL

Accessories

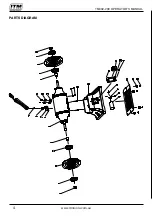

The bench grinder is supplied with the following accessories:

2 eye shields with mounting brackets and 2 tool rests

CAUTION. Always ensure that the bench grinder is switched off and plug is removed from the power

point before making any adjustments.

To fit the eye shields locate the nut, screw and washers provided through the slot in the eye shield and

hole on the grinding wheel guard and finger tighten. Position the eye shield so it does not come in to

contact with the grinding wheel. Tighten the nut and screw to secure the eye shield in place.

Attach the tool rests using the bolts and securing knobs provided and adjust to the correct position. The

gap between the tool rest and grinding wheel should be set to 2mm.

Bench Mounting

The Grinder can be secured with screws or nuts and bolts. Locate the mounting holes. The length of

the bolts or screws will depend on the thickness of the bench. Where a steel bench is used, it is best to

mount the grinder on to a board, then attach the board to the bench, this will also minimize vibration.

Switching On And Off

Before connecting to the power supply rotate the wheel by hand to ensure that it is running properly and

free from obstruction. Connect to the mains supply and press the rocker switch to the ON position (l).To

stop the machine simply press the rocker switch to the OFF position (o).

General Inspection

Regularly check that all the fixing screws are tight. They may vibrate loose over time.

GETTING STARTED

9

www.itmtools.com.au