Visit:

www.abisupport.com

20

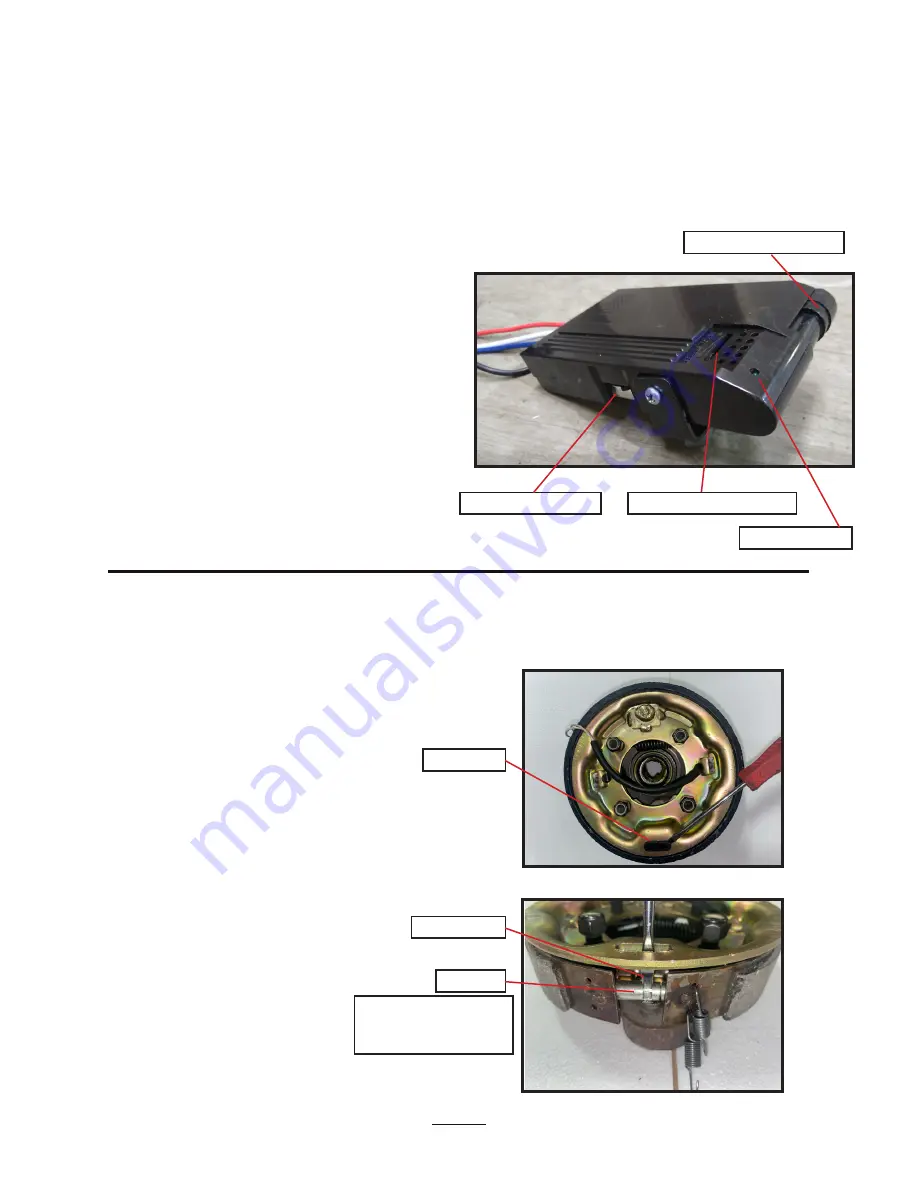

Brake Controller Adjustments

Brake Shoe Manual Adjustments

A NOTE: The electronic braking system is not

compatible with ALL tow vehicles. Please contact

ABI for more information: 877-788-7253 or log on to

ABIsupport.com.

ABI offers power brakes as a standard feature on the dual

axle Workman XL only. Mounted within the black

box on the Workman XL Trailer is a Brake Controller, which

allows adjustment to the time delay and power intensity

of the trailer brakes.

First, make sure power is being supplied to the brake

controller by hooking up the 4-pole wire connection to

the ATV and turning on the ATV ignition.

NOTE:

Be sure to

have a strong, well charged battery for full braking power.

Squeeze the Manual Brake Activator and note that red

lights appear by the Power Intensity Adjuster. The more

lights that activate, the more stopping power applied to

the Workman XL trailer brakes.

More Stopping Power:

Move the Power Intensity Adjuster

to the Left, towards the (+) positive symbol.

Less Stopping Power:

Move the adjuster to the Right

towards the (-) negative symbol.

After using your trailer for some time, you may need to

manually adjust the brake shoes located within the brake

drum. At the bottom, inside portion of each brake hub

you will note an elongated plastic cap. Remove this cap as

indicated (

Fig 61

).

Inside the hole of the hub, you will note a silver adjuster.

Insert a brake spoon or a screwdriver into the hole, and

spin the teeth down to expand or add more stopping

power to each hub (

Fig 62

). Spin the teeth up to contract

or decrease the brake pads from contacting the brake

drum. The direction ‘down’ would be to spin the circular

adjuster in a direction towards you. Imagine the adjuster

to be like a coin rolling on a table towards you, that is the

direction of ‘down’.

The brake hub in these views has been removed from the

axle for illustrative putposes only.

The Time Delay Adjuster allows to place a 1-3 second delay

when applying the trailer brakes. Check that the switch is

pushed to the back, in the opposite direction of the power

on Light, for instant stopping power. The factory default is

set to instant stopping or no delay.

Manual Brake Activator.

Power Intensity Adjuster.

Time Delay Adjuster.

Pastic Cap.

Screwdriver.

Adjuster.

Spin the teeth on the

Adjuster down for more

stopping power.

Power On Light.

Fig 61.

Fig 62.