EN

-

8

4 Putting into operation

TIG welding torch

4.1 Setting up the torch body

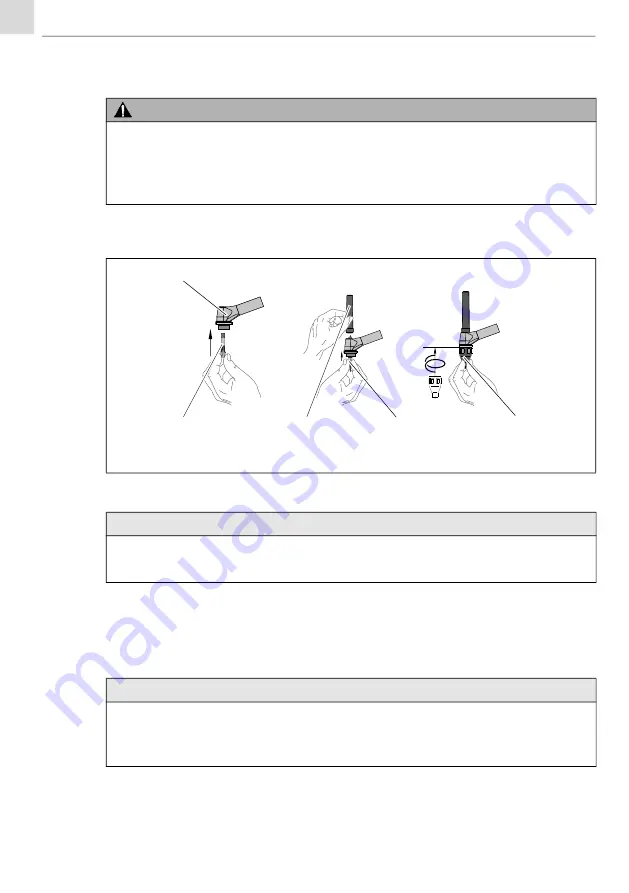

Equip the torch neck according to the following figure:

4.2 Shortening the tungsten electrode

The electrode type is set by EN ISO 6848. The maximum electrode length depends on the torch

type.

4.3 Connecting the cable assembly

1

Plug the hose assembly connection into the power source and secure it with a connection nut.

2

Properly mount the connections for water supply/return, shielding gas and control line plug.

CAUTION

Risk of injury

Puncture or cut-in wounds may be caused by the wire electrode.

• Keep your hands out of the danger zone.

• Wear the correct protective gloves.

1

Torch body

2

Gas nozzle

3

Tungsten electrodes

4

Back cap

5

Electrode holder

Fig. 1

Step 1-4

NOTICE

• Instead of the electrode holder, you may also use a gas diffuser. Due to its design, it will

produce a laminar gas flow.

Step 1

Step 2-3

Step 4

1

5

3

4

2

NOTICE

• The welding performance is affected by the selection of the tungsten electrode and by

wear. A smooth, groove-free sharpened end of the tungsten electrode has a positive effect

on the welding result.