- 8 -

ENSURE ALL FILTERS ARE FITTED CORRECTLY PRIOR TO USING THE MACHINE. ENSURE THE

AIRFLOW ARROW ON THE FILTER POINTS THE CORRECT WAY.

Filtration

The machine employs a multi-stage filtration process. Contaminated air enters the machine from the process and is

passed through a pre-filter which removes larger particles. This filter can be cleaned by using the air fitting to direct

compressed air through the filter. This is captured in the debris tray for easy removal. The pre-filter prevents

premature blockage of the main filter. The HEPA section of the main filter removes 99.997% of particles larger than 0.3

microns in size and 95% of particles over 0.01 microns in size. The chemical filter section of the main filter removes toxic

gases. The purified air is then returned to the workplace. The contents of filters can vary depending on their application.

Please ensure you have specified the correct filter for your application.

Important note

Always check the following points for debris build up before changing any filter. This avoids false alerts related to airflow.

•

Extraction nozzle

•

Flexible hose and any pipework

•

Air inlet

Changing filters

The machine will warn you if a filter is blocked (see control system). Always wear the apprioriate PPE when coming into

contact with used filters. Take care when removing main filters as they can be heavy.

Opening the machine

It is important that the correct procedure below is followed when opening the machine. Failure to do so will result in your

process operating without extraction which is an Occupational Health & Safety hazard.

•

Ensure your process is stopped

•

Switch off your Purex machine at the control panel (see control system)

•

Release the catches on the lid

•

Remove the lid

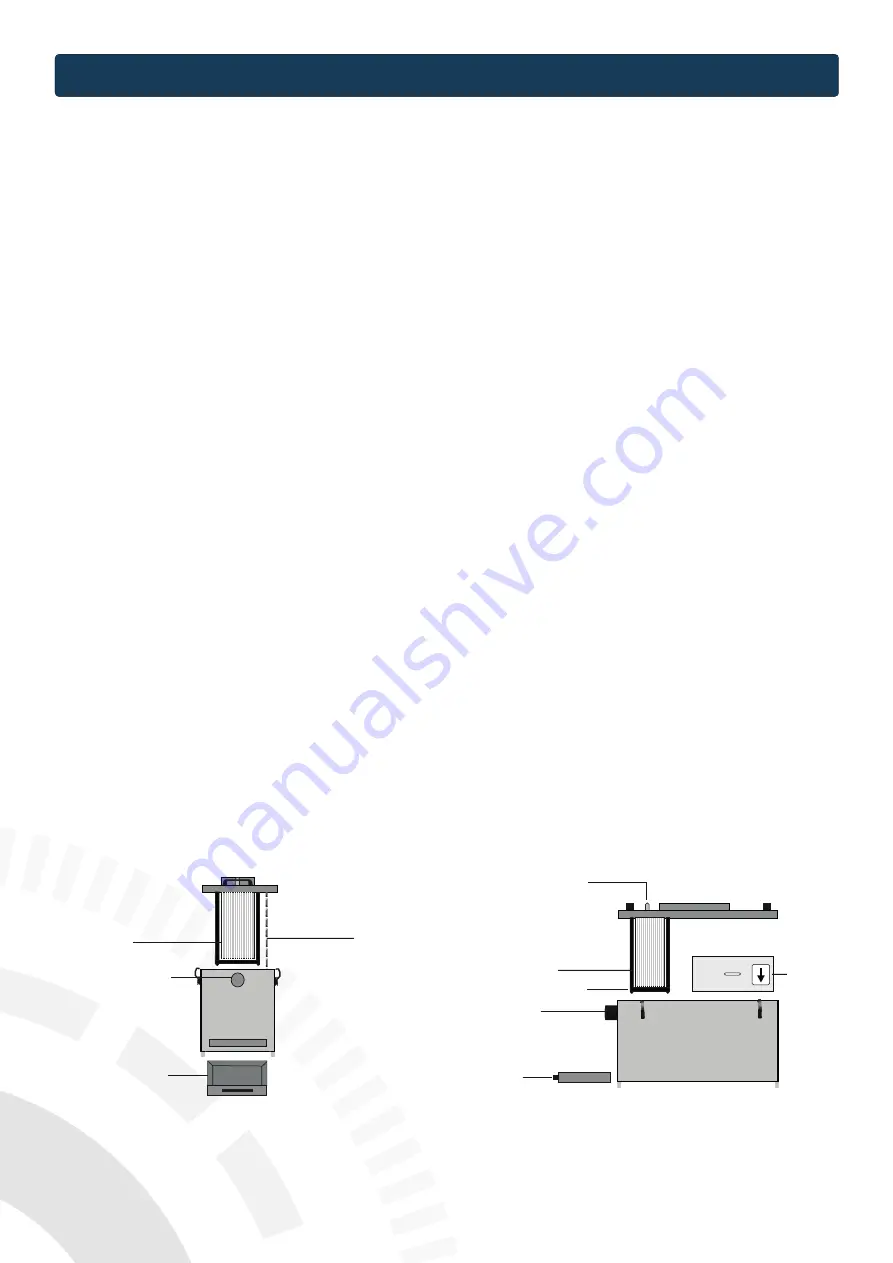

FILTRATION & CHANGING FILTERS

1

2

3

4

2

3

5

6

1

7

LEGEND:

1. Air Inlet

2. Pre-filter

3. Debris tray

4. Earth strap (internal)

5. Compressed air connector

6. Main filter (HEPA/carbon location

7. Pre-filter compression plate