EN

-

54

10 Faults and troubleshooting

iROB

®

501, iROB

®

401, iROB

®

301

10 Faults and troubleshooting

► Observe the documentation for the welding components.

► Contact your retailer or ABICOR BINZEL in the event of questions or problems.

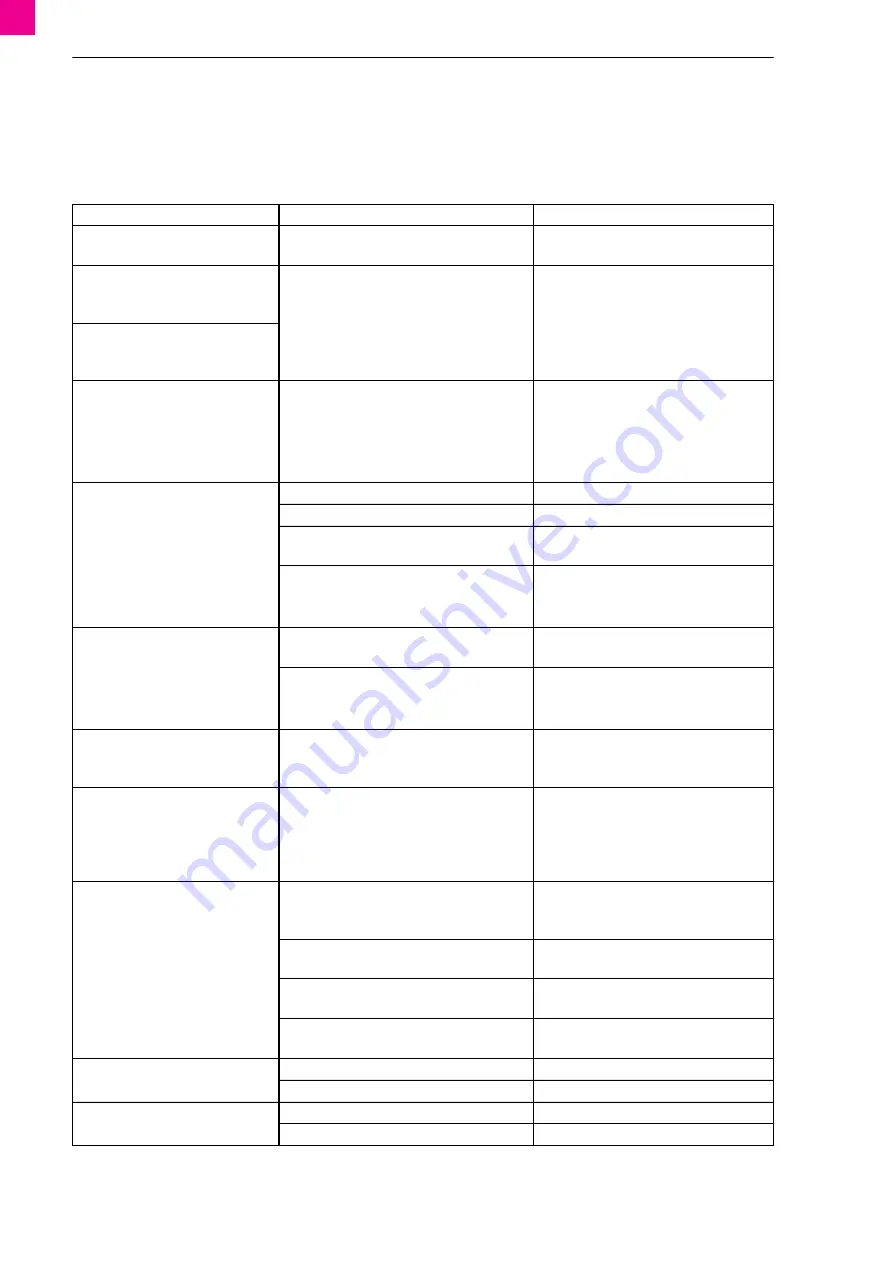

10.1 General faults

Tab. 18

General faults and troubleshooting

Fault

Cause

Troubleshooting

Fuse has blown.

There is excess current, overvoltage, or a short

circuit.

► Do not turn on the device. Contact the

service department.

The mains LED does not

illuminate, not even when

the machine is switched on.

Primary power supply is not supplied.

► Supply the primary power supply

with 340 to 460 V.

Nothing is displayed in the left

digital display, not even when

the machine is switched on.

The temperature LED is

illuminated and an error

message is displayed as soon

as the welding power source

is switched on.

The protective circuit has been triggered due to

overheating.

1

Stop all welding operations and allow

the fans to run for 10 minutes or longer.

2

Switch off the device.

3

Clean the device’s interior.

Shielding gas does not flow.

The gas cylinder’s valve is closed.

► Open the gas valve.

The pressure in the gas cylinder is insufficient.

► Replace the gas cylinder.

The settings and connection for the external

inputs are not correct.

► Check the settings of internal functions

F29 to F32.

External input lines are not connected or are

short-circuited.

► Check the lines connected to the external

input terminal for damage.

► Replace lines if necessary.

Shielding gas flows

continuously.

The settings and connection for the external

inputs are not correct.

► Check the settings of internal functions

F29 to F32.

External input lines are not connected or are

short-circuited.

► Check the lines connected to the external

input terminal for damage.

► Replace lines if necessary.

Current and voltage cannot

be set.

The <Parameter setting> knob is defective.

► Have printed circuit board PCB2

(P30086R00) replaced. Contact the

service team.

Welding parameters cannot be

set via the control panel.

Welding mode does not change

even if it is switched on the

control panel.

Control panel lock is active.

► Press and hold <Enter> for at least

3 seconds to deactivate the control

panel lock.

Arc is unstable.

The welding parameter setting is incorrect.

► Check the setting for the welding wire

material, welding wire diameter, and

shielding gas type.

Welding wire material is wrong or wire feed is

faulty.

► Check if there is a problem with the

welding wire or wire feed.

Voltage test lead is not connected correctly.

► Check the connection of the voltage

test lead.

A noise signal is interspersed in the voltage

test lead.

► Adjust the arc characteristics on the

pulse side.

Welding wire is not fed. No

error message is displayed.

The counter-pressure roll is not making contact. ► Correctly set the pressure roll.

Fault in the wire guide.

► Check the wire guide lines.

Pores appear.

There is a problem with the shielding gas.

► Check the gas cylinder and hoses.

The pipe’s contact pipe is worn.

► Replace the contact pipe.