EN

-

56

10 Faults and troubleshooting

iROB

®

501, iROB

®

401, iROB

®

301

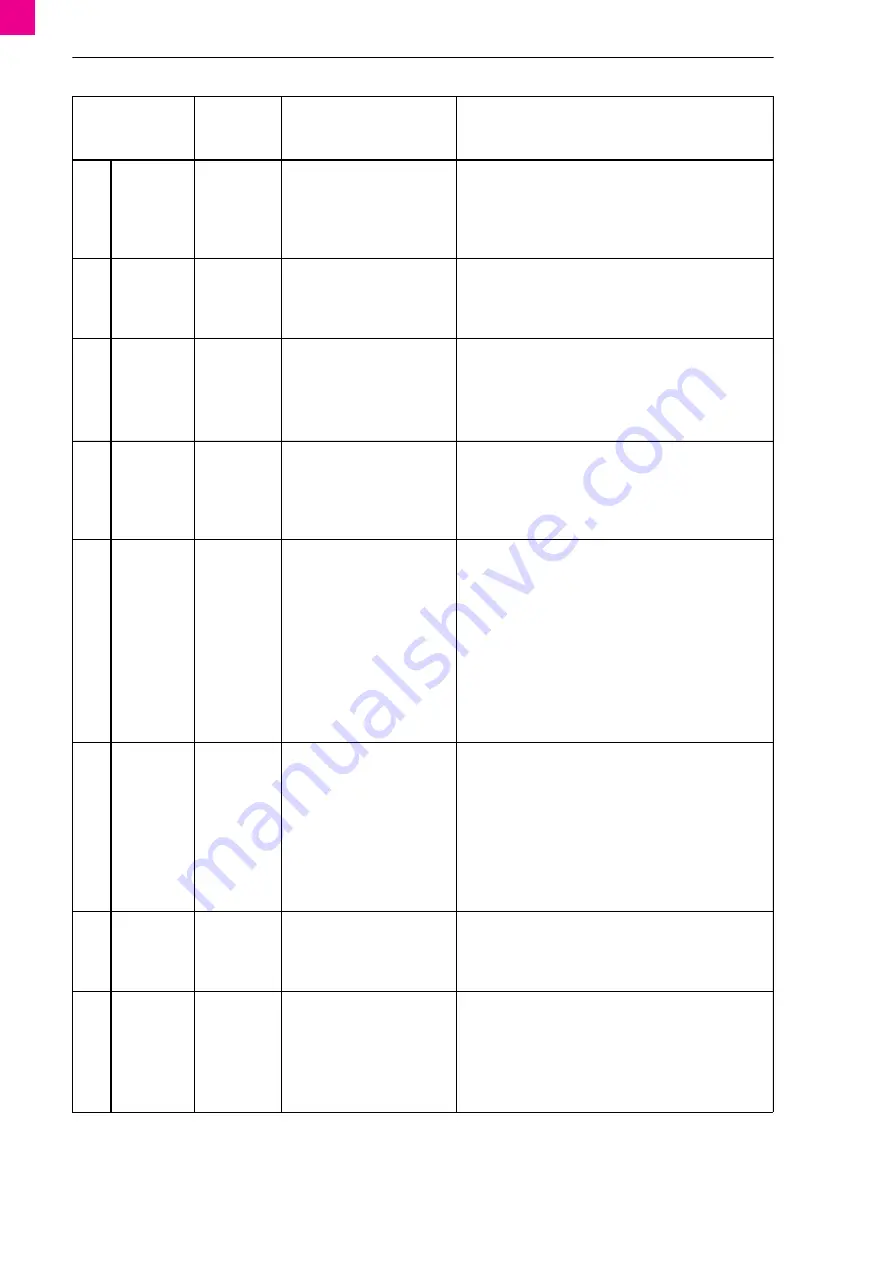

E-

100

1

Fault in the control voltage.

► If the welding power source is connected to other

devices, check all connection lines for abnormalities

(e.g. short circuits).

The error message is canceled when the welding power

source is switched off.

E-

150

1

Primary input voltage has

exceeded the permissible range.

► Check whether the primary input voltage is

between 340 and 460 V.

The error message is canceled when the welding power

source is switched off.

E-

160

2

Primary input voltage has fallen

below the permissible range.

► Check whether the primary input voltage is

between 340 and 460 V.

► Check the set value of the internal function F20.

The error message is canceled when the welding power

source is switched off.

E-

210

1

Arc voltage was not detected.

► Check whether the welding current supply line, the

welding current return line, and the voltage test lead are

properly connected.

The error message is canceled when the welding power

source is switched off.

E-

300 to 303

1

The temperature inside the

welding power source has

exceeded the permissible range.

1

Stop all welding operations and allow the fans to run

for 10 minutes or longer.

2

Switch off the device.

3

Clean the device’s interior.

9.2 Cleaning the device on page EN

The error message is canceled when the welding power

source is switched off.

► After restarting, ensure that the permissible duty cycle is

not exceeded.

E-

310 to 313

2

The fans are not rotating.

The fan may be blocked by dust accumulation or foreign

objects.

► Clean the inside of the welding power source.

9.2 Cleaning the device on page EN

If the problem persists, the fan may be defective.

► Contact the service team.

The error message is canceled when any button on the

control panel is pressed.

E-

510

1

Fault in the cooling water pump

of the optional cooling unit.

► Check the water pump and hoses for leaks and ensure

the coolant levels are sufficient.

► If an air-cooled torch is used, ensure that the LED above

the <Cooling unit on/off> button is not illuminated.

E-

615

2

Fault in the stored backup data. The specified welding parameters and setting of the internal

functions may need to be initialized.

► After the fault has been remedied, make sure that the

data is not corrupted.

The error message is canceled when any button on the

control panel is pressed.

Tab. 19

Fault codes on the control panel and their remedy

Fault code

Type of fault

1 = alarm

2 = warning

Cause of fault

Measure