EN - 18

BAL.0523.0 • 2019-10-17

6 Commissioning

iSTM mini

5

Screw in the wire brake

through the opening in the protective cap

and connect the compressed air hose

6

Insert the shielding gas hose

and connect it to the shielding gas supply.

7

Connect the compressed air hose

to the compressed air supply (no illustration).

8

Connect the coolant lines

.

Connecting the coolant

Each time the device is commissioned or after each cable assembly change, the cooling system must be purged of any air.

Carry out the following activities:

1

Disconnect the coolant return hose from the coolant recirculator and disconnect the coolant connection from the power

source and empty the hose above the collecting device.

2

Seal the opening on the coolant return hose. Then re-open it by abruptly releasing it. Repeat this process until the coolant

flows into the collection receptacle continuously and without air bubbles.

3

Switch off the coolant recirculator and reconnect the coolant return hose.

6.3 Attaching the ABIROB

®

G torch neck

WARNING

Risk of burns

The torch will become overheated when welding without coolant or if the coolant level is

too low.

• Wear the correct protective gloves.

• Check the coolant level at regular intervals.

NOTICE

• Ensure that the coolant supply and return hoses have been correctly installed. Coolant supply = blue, coolant return =

red

• Do not use deionized or demineralized water as coolant or for leak and flow tests.

This may shorten your welding torch’s service life.

• For liquid-cooled welding torches, we recommend using

ABICOR BINZEL

BTC coolant.

Please consult the applicable safety data sheet.

1

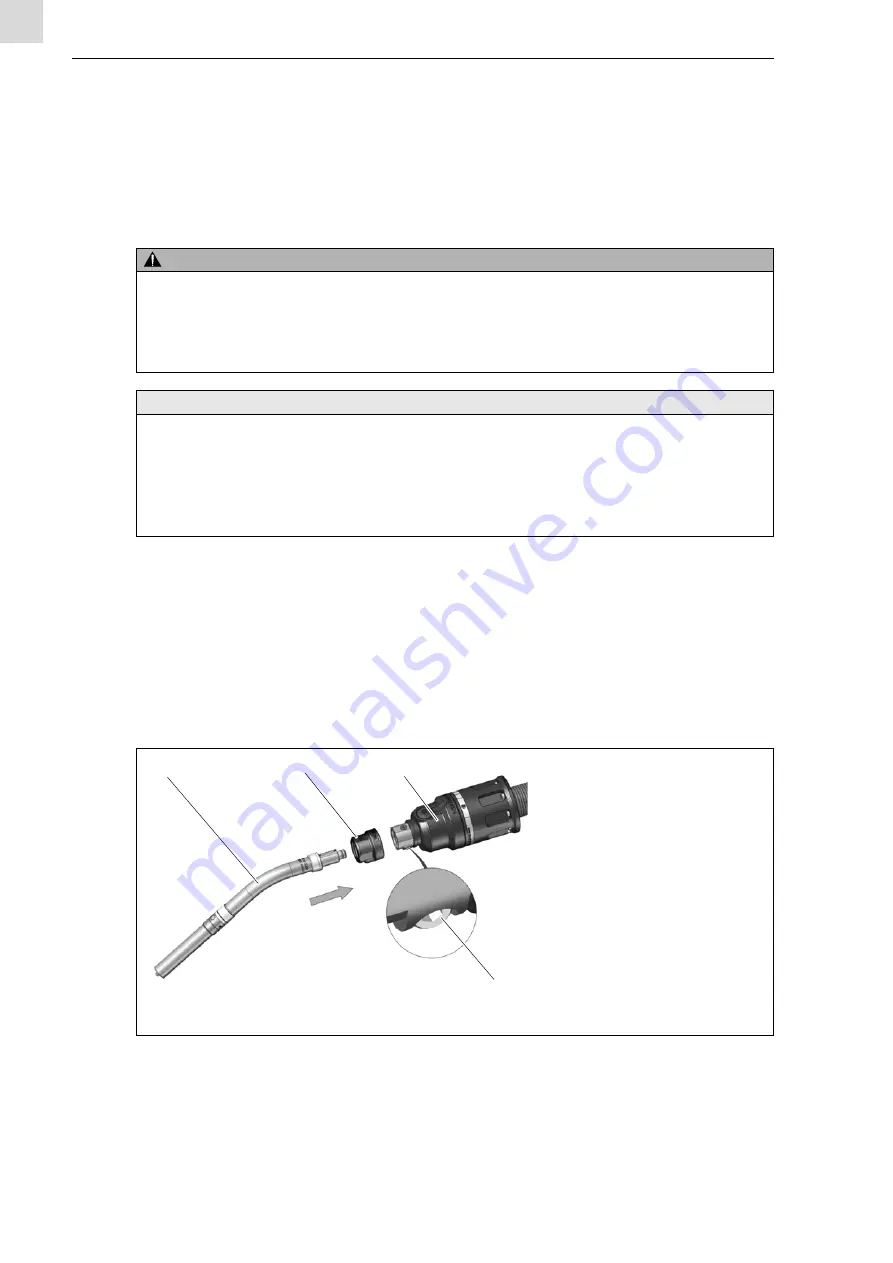

Torch neck

2

Protective cap

3

iSTM mini

4

Cylinder head screw M5 × 10

Fig. 15

Attaching the

ABIROB

®

G

torch neck

1

2

3

4

Mou

nting

dire

ction