iSTM mini

6 Commissioning

BAL.0523.0 • 2019-10-17

EN - 15

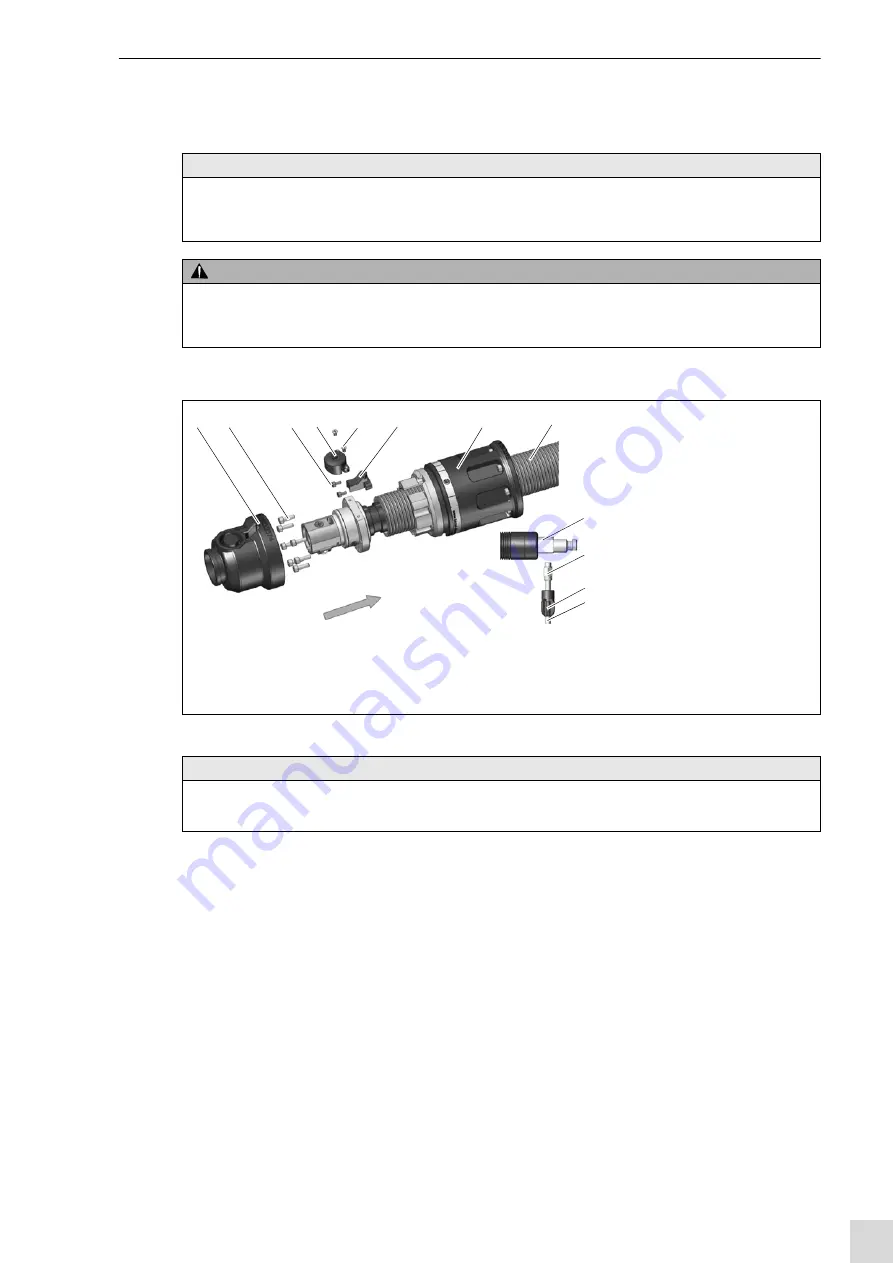

6.2.2 Attaching the cable assembly to the robot

iSTM mini for ABIROB

®

G

1

is guided through the mounted iSTM mini welding torch interface

. Mount the cable assembly

in the mounting direction.

2

Disassemble the straight push-in fitting

3

Mount the cable assembly

with seven cylinder head screws M4 × 16

on the iSTM mini

. Max. tightening

torque M = 4 Nm.

4

on the iSTM mini with 2 cylinder head screws M3 × 6

.

5

with 2 countersunk screws DIN 965 M3 × 5

on the cable assembly.

6

Mount the cover on the iSTM mini

7

Tighten the push-in fitting Ø 6 using the screw-in aid AF11.

8

Insert the shielding gas hose and connect it to the shielding gas supply.

NOTICE

• After mounting is complete, check for any leaks.

• All leads (shielding gas, compressed air lines, and coolant hoses) must be mounted torsion-free and with sufficient

play.

WARNING

Risk of injury

Serious injuries may be caused by parts swirling around.

• When cleaning with compressed air, wear suitable protective clothing, in particular safety goggles.

1

Cover

2

Cylinder head screw M4 × 16

(7 pieces)

3

Cylinder head screw M3 × 6

(2 pieces)

4

Front cover

5

Countersunk screw M3 × 5

(2 pieces)

6

Rear cover

7

iSTM mini

8

Cable assembly

9

Machine-side connector

10

Push-in fitting Ø 6/G1/8"

11

Screw-in aid AF11

12

Shielding gas hose Ø

6

Fig. 11

Mounting the cable assembly

iSTM mini

for

ABIROB

®

G

NOTICE

• The welding current port must be connected to the wire feeder.

Operating instructions for the wire feeder

Mou

nting

dire

ction

1

2

3

4

5

6

7

8

9

10

11

12