Absco Industries

Assembly Instruction Manual

ABSCO SPACE SAVER SHED

MODEL: 15151SK

1.52mW x 1.52mD x 1.80mH, 2.08mH

Model: 15151SK

14/08/18

1.2

16

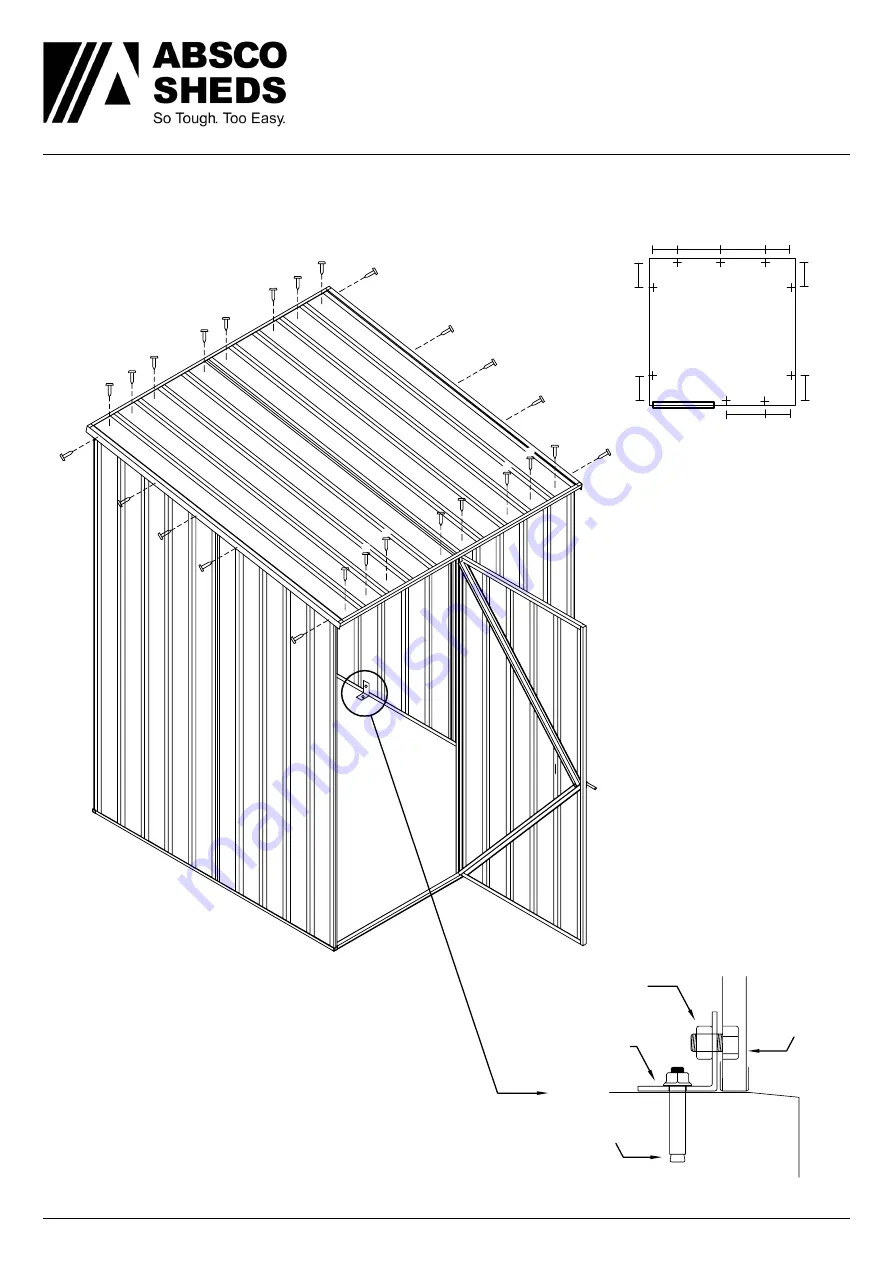

FINAL CONSTRUCTION

Each anchor consists of one nut, bolt, M10

dynabolt and steel angle.

Drill a 10mm hole into the wall sheet.

Drill a 10mm hole into the concrete.

Bolt and Nut*

M10 4.6/S

Steel Angle*

35 x 35 x 3

M10 Dynabolt*

* Denotes hot dip galvanised fi nish

Wall Sheet

Slab

Location of 9

concrete anchors

250

250

250

250

250

250

510

480

510

250

ANCHORING OF SHED

D

D

D

D

D

D

D

D

D

D