10

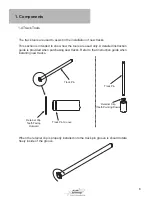

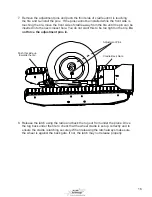

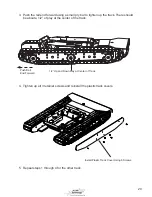

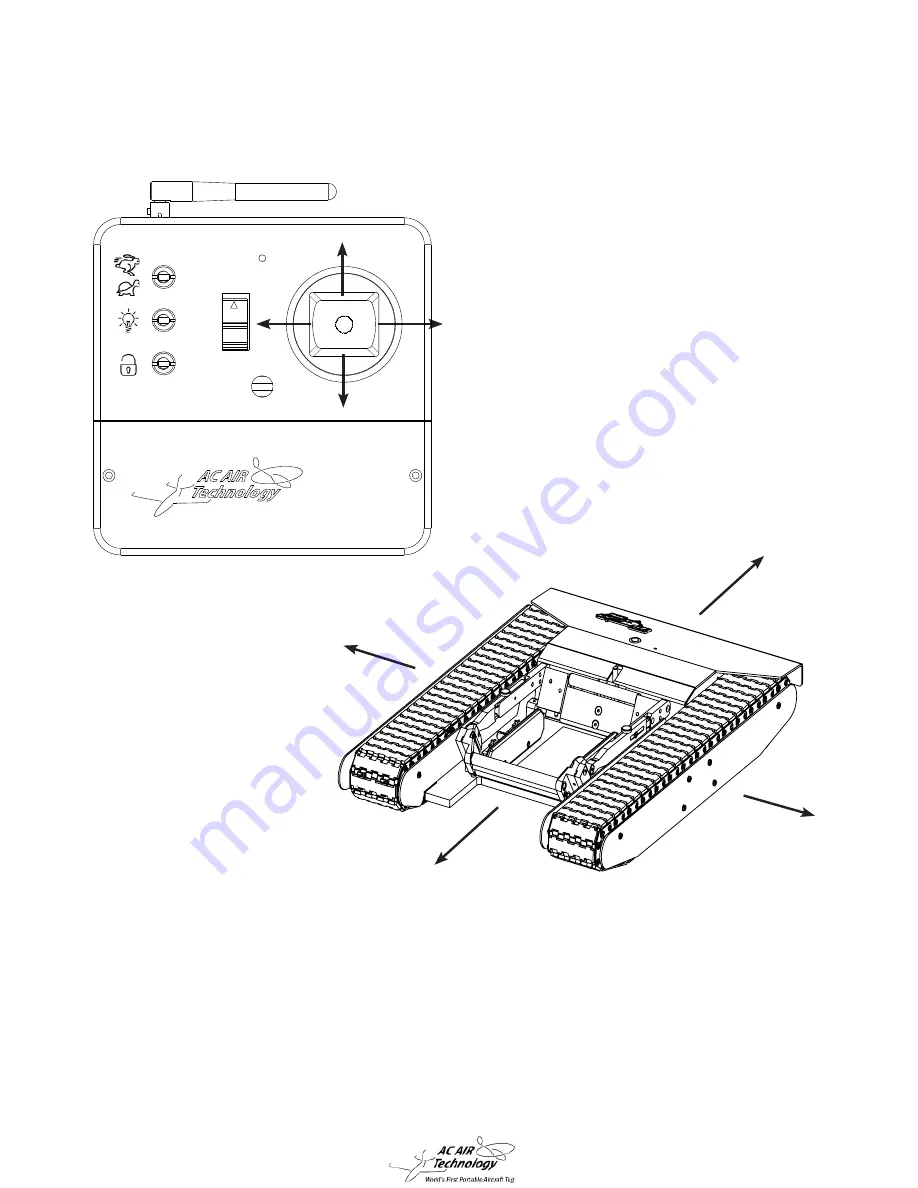

2. To drive the tug, move the control stick in the desired direction.

Forward

Right

Reverse

Left

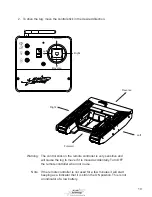

ON

Reverse

Right

Forward

Left

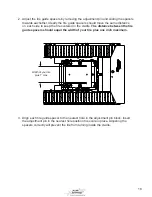

If the remote controller is not used for a few minutes it will start

beeping as a indicator that it is still in the ON position. This is not

an indicator of a low battery.

The control stick on the remote controller is very sensitive and

will cause the tug to move if it is moved accidentally. Turn OFF

the remote controller when not in use.

Warning:

Note: