20

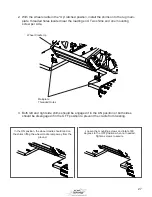

2-5 Adjusting the Wheel Cradle

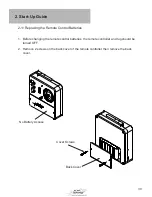

2. Start-Up Guide

Wheel cradle in the down position

1. Make sure that the wheel cradle is down. If needed, use the radio to unlatch the

cradle.

2. Place wheel chocks behind the rear tires of the plane to ensure the plane does not

roll backwards.

3. Drive the tug under the wheel of the plane until the wheel cradle locks in the upright

position.