Ƹ

6. Indoor

Unit

Wire

Connection

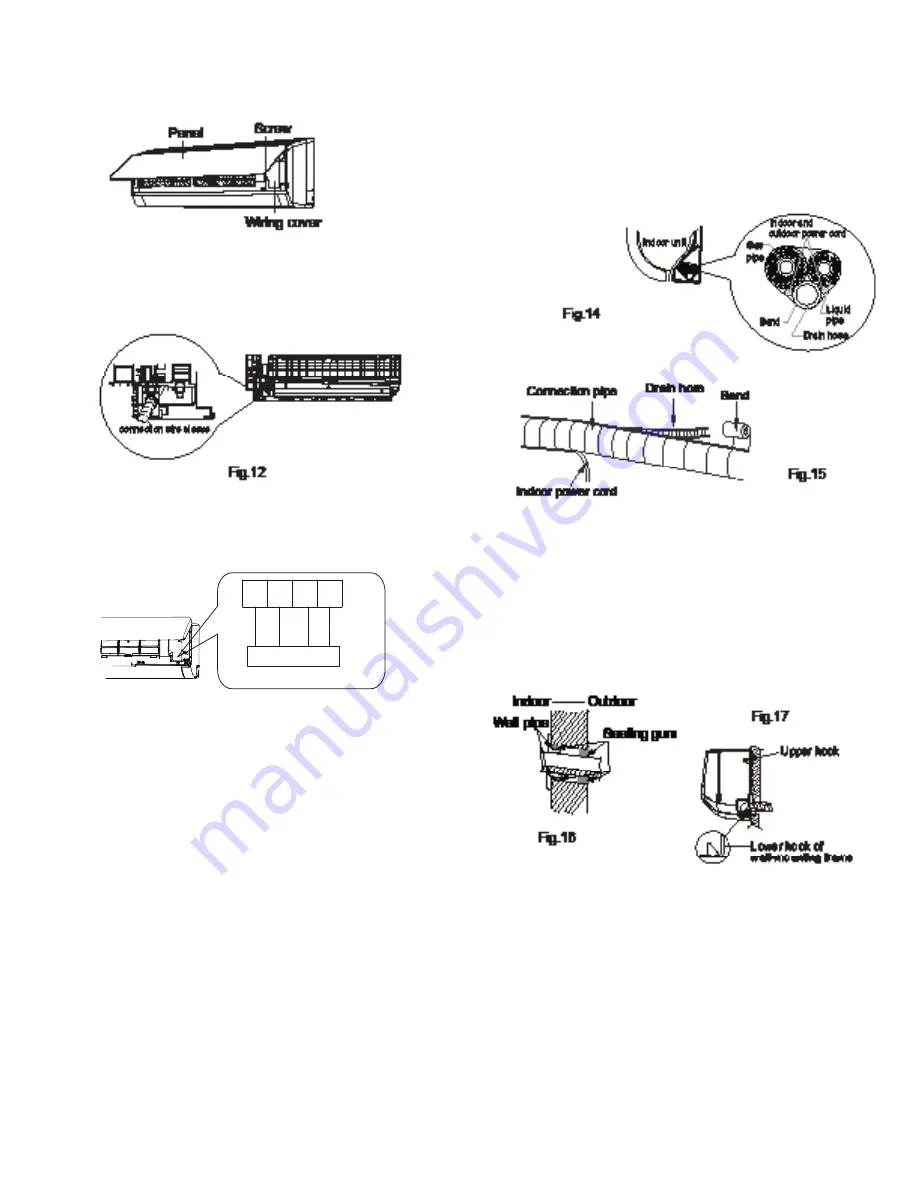

• Open panel. Remove screw on wiring panel and detach

cover (Shown in Figure #11 below).

•

Affix the wire crossing board on the connection wire sleeve

to the bottom of the case. Position the connection wire

sleeve through the wire crossing hole at the back of the

indoor unit. Pull through front (Shown in Figure #12

below).

• Remove wire clip. Attached power connection wire to the

wiring terminal by color. Tighten screw(s) and attach power

connection wire with wire clip (Shown in Figure #13 below).

• Wiring board is for reference only.

• Replace wire cover back and tighten screw.

• Close

panel.

!

Ì

Note:

• All wires for both indoor and outdoor units MUST be

connected by a professional.

• If the length of the power supply connection cable is

insufficient, contact the supplier for a new one.

• Units that contain plugs MUST have plugs in convenient/

reachable location.

• Units without plugs MUST have an air switch installed in

the line. The air switch MUST be all-pole parting and the

contact distance MUST be more than 1/8”.

7. Bind up Pipe

•

Bind the connection pipe, power cord and drain hose with

band. Shown in Figure #14 below).

• Reserve a length of drain hose and power cord for installation

during binding. When binding to a specific degree, separate

the indoor power and separate the drain hose (Shown in Figure

#15 below).

• Bind all cordage and hoses evenly.

• The liquid and gas pipes should be bound separately at the

end.

!

Ì

Note:

• The power cord and control wire cant be crossed or winding.

• The drain hose should be bound at the bottom.

8. Hang the Indoor Unit

•

Insert bound pipes in to wall pipe and pass them through hole

in wall.

• Hang indoor unit on the wall mounting frame.

• Stuff gap between pipes and wall hole with sealing gum.

• Affix the wall pipe (Shown in Figure #16 below).

•

Ensure indoor unit is close to the wall and installed securely

(shown in Figure #17 below).

!

Ì

Note:

• DO NOT excessively bend the drain hose. Doing so may

cause a blockage.

outdoor unit connection

white

(blue)

black

red

(brown)

L1'

S L2'

G

green

(yellow-green)