7

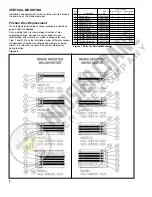

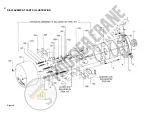

FOR 3-PIECE COUPLED INPUT REDUCERS (Reference Figure 3)

FOR CLAMP COLLAR INPUT REDUCERS (Reference Figure 4)

View the coupling assembly through the access hole in the C-face adapter.

1. Make sure the couplings jaws fully engage the spider. If they do not, loosen

the setscrew in the reducer coupling half and slide it forward until full jaw

engagement is achieved. However, make sure the jaws on one coupling half

do not contact the hub of the other coupling half.

2. Reaching through the access hole in the C-face adapter with a hex

key, tighten the coupling setscrew on the reducer coupling half to the

recommended torque given below.

View the clamp collar through the access holes in the C-face adapter.

1. Rotate the clamp collar to locate the setscrew over the key, if necessary.

2. Tighten the setscrew to the torque referenced below.

3. Reach through the access hole in the C-face adapter with a hex socket and

tighten the clamp collar clamping bolt to the torque value given below.

Replace the access hole plugs in the C-face adapter.

Replace the access hole plugs in the C-face adapter.

NOTE: A TEE handle hex key wrench is not stiff enough to properly

tighten the coupling setscrews. A large diameter socket wrench

extension with a short hex key insert must be used in conjunction with a

torque wrench. Failure to tighten the setcrews to the proper torque may

result in movement between shafts and coupling components and cause

premature wear on the shafts, coupling and keys.

NOTE: A TEE handle hex key wrench is not stiff enough to properly

tighten the clamp collar bolt. A socket wrench extension with a hex

insert must be used in conjunction with a torque wrench. Failure to

tighten the clamp collar to the proper torque may result in movement

between motor and reducer shafts and cause premature wear on the

shafts and keys.

FOR 3-PIECE COUPLED INPUT REDUCERS

Reference Figure 3

FOR CLAMP COLLAR INPUT REDUCERS

Reference Figure 4

NEMA

Motor

Frame

Coupling

Size

Setscrew

Size

Setscrew

Tightening Torque

Motor Coupling

Half Position

Dimension “X”

NEMA

Motor

Frame

Clamp

Bolt

Clamp Bolt

Tightening Torque

Setscrew

Size

Set Screw

Tightening Torque

56

19

M5

18 lb-in (2 Nm)

0

56

M6

132 lb-in (15 Nm)

M4

27 lb-in (3 Nm)

140

19/24

M5

18 lb-in (2 Nm)

0

140

M6

132 lb-in (15 Nm)

M4

27 lb-in (3 Nm)

180

24/28

M5

18 lb-in (2 Nm)

0

180

M8

312 lb-in (35 Nm)

M6

90 lb-in (10 Nm)

210

28/38

M6

42 lb-in (4.8 Nm)

0

210

M10

600 lb-in (68 Nm)

M8

220 lb-in (25 Nm)

250

38/45

M8

90 lb-in (10 Nm)

0

250

M8

312 lb-in (35 Nm)

M6

90 lb-in (10 Nm)

280

42/55

M8

90 lb-in (10 Nm)

0

280

M8

312 lb-in (35 Nm)

M6

90 lb-in (10 Nm)

320

48/60

M8

90 lb-in (10 Nm)

0

320

M10

600 lb-in (68 Nm)

M8

220 lb-in (25 Nm)

360

55/70

M10

150 lb-in (17 Nm)

0

360

M10

600 lb-in (68 Nm)

M8

220 lb-in (25 Nm)

IEC

Motor

Frame

Coupling

Size

Setscrew

Size

Setscrew

Tightening Torque

Motor Coupling

Half Position

Dimension “X”

IEC

Motor

Frame

Clamp

Bolt

Clamp Bolt

Tightening Torque

Setscrew

Size

Set Screw

Tightening Torque

71

19

M5

18 lb-in (2 Nm)

0

71

M6

132 lb-in (15 Nm)

M4

27 lb-in (3 Nm)

80

19/24

M5

18 lb-in (2 Nm)

0

80

M6

132 lb-in (15 Nm)

M4

27 lb-in (3 Nm)

90

19/24

M5

18 lb-in (2 Nm)

0

90

M8

312 lb-in (35 Nm)

M6

90 lb-in (10 Nm)

100

24/28

M5

18 lb-in (2 Nm)

0

100

M8

312 lb-in (35 Nm)

M6

90 lb-in (10 Nm)

112

24/28

M5

18 lb-in (2 Nm)

0

112

M8

312 lb-in (35 Nm)

M6

90 lb-in (10 Nm)

132

28/38

M6

42 lb-in (4.8 Nm)

0

132

M10

600 lb-in (68 Nm)

M8

220 lb-in (25 Nm)

160

38/45

M8

90 lb-in (10 Nm)

0

160

M8

312 lb-in (35 Nm)

M6

90 lb-in (10 Nm)

180

42/55

M8

90 lb-in (10 Nm)

0

180

M8

312 lb-in (35 Nm)

M6

90 lb-in (10 Nm)

200

42/55

M8

90 lb-in (10 Nm)

0

200

M10

600 lb-in (68 Nm)

M8

220 lb-in (25 Nm)

225

48/60

M8

90 lb-in (10 Nm)

0.040 in (6.0 mm)

250

55/70

M10

150 lb-in (17 Nm)

0

WARNING: The DODGE QUANTIS ILH and its connected

equipment and accessories must be guarded. Rotating parts

such as couplings, pulleys, fans and unused shaft extensions

must be permanently guarded by the user against accidental

contact with personnel and their clothing. The surface

temperature of the DODGE QUANTIS ILH enclosure may

reach temperatures which can cause discomfort or injury to

personnel accidentally coming into contact with hot surfaces.

The user should provide guards to prevent accidental

contact with hot surfaces. Guards must be sufficiently rigid

to maintain adequate guarding in normal service.

WARNING: Threaded hardware used to mount the DODGE

QUANTIS ILH Unit must be SAE Grade 5 or Metric Class 8.8

or better. DO NOT USE HARDWARE OF A LOWER GRADE.

MAINTENANCE

Check oil levels and oil quality regularly. Change oil at the intervals

specified in the Lubricants section of this document. Check

alignments of drive components regularly. Check chain and belt

tensions and hardware tightness periodically too.

Summary of Contents for LOUDEN 200 Series

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ...FIGURE 8 FIGURE 9 FIGURE 10 FIGURE 11...

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......