35

TROUBLESHOOTING (Continued)

BEDKNIFE GRINDING

--POSSIBLE CAUSE--

--REMEDY--

--REASON--

--PROBLEM--

Direct coolant into the grinding

wheel, at the point of the grind.

See Operators Manual.

Take off about .002 to .003"

[.05 to .075mm] per pass

during rough grind. See

Operators Manual.

Dress the wheel before the

finish-grinding pass on each

bedknife. See Operators

Manual.

Dress the wheel before the

finish-grinding pass on each

bedknife. See Operators

Manual.

Take off about .002 to .033"

[.05 to .075 mm] per pass

during rough grind. See

Operators Manual.

Set the traversing speed to 12

FT/MIN.

Visually check the outside-

diameter run out while slowly

rotating the wheel. Also check

the motor without a wheel

installed. Replace the wheel if

out-of -round.

Loosen wheel flange and rotate

the wheel 90°. Hand tighten

wheel flange and retry. Repeat

process 3 times if necessary.

The top face of

the bedknife

shows burn

marks from being

too hot.

Grinding wheel is

glazing too

quickly.

Grinding motor

vibrates exces-

sively.

When the front face of the

bedknife gets too hot, the

steel loses its temper

(softens).

Too much stock removal in

one pass creates too much

heat and softens the steel.

Wheel will glaze if not

dressed often enough.

Also, as a general rule, use

a higher traverse speed for

the heavy grind.

Wheel will glaze if not

dressed often enough. If

grinding wheel is not

extended 1/2" [12 mm] over

bedknife, it will glaze more

quickly because there is

less dressing.

Too light a grinding cut

doesn't permit enough

dressing action on the

wheel, so it glazes.

Too slow a traverse speed

can cause excessive heat

buildup in the grinding

wheel, which glazes the

wheel.

A grinding wheel which isn't

properly trued up on outside

or inside diameters can

vibrate excessively and

transfer that vibration to the

motor.

A--Coolant not directed onto

the bedknife and grinding

wheel.

B--Too heavy stock removal

during grinding.

C--Grinding wheel is glazing.

A--Wheel needs dressing.

B--Too light a cut when rough

grinding.

C--Grinding head is traversing

too slow.

Grinding wheel is out of

balance.

Summary of Contents for 670

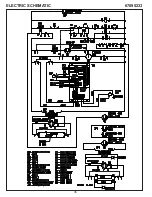

Page 36: ...36 ELECTRIC SCHEMATIC 67095233 ...

Page 38: ...38 PARTS LIST 6709534 MAIN BASE ASSEMBLY ...

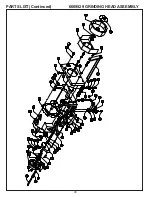

Page 40: ...40 PARTS LIST Continued 6609529 GRINDING HEAD ASSEMBLY ...

Page 42: ...42 PARTS LIST Continued 6709531 TRAVERSE CARRIAGE ASSEMBLY ...

Page 44: ...44 PARTS LIST Continued 6709533 BEDKNIFE SUPPORT ASSEMBLY ...

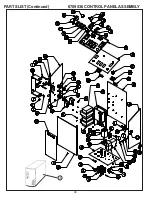

Page 46: ...46 PARTS LIST Continued 6709536 CONTROL PANEL ASSEMBLY 50 ...

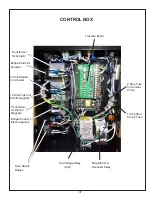

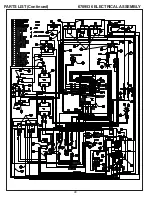

Page 48: ...48 PARTS LIST Continued 6709536 ELECTRICAL ASSEMBLY ...

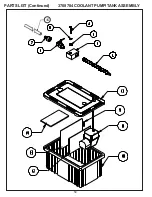

Page 50: ...50 PARTS LIST Continued 3708784 COOLANT PUMP TANKASSEMBLY 15 ...

Page 52: ...52 ...