Summary of Contents for 670

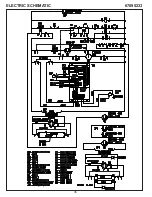

Page 36: ...36 ELECTRIC SCHEMATIC 67095233 ...

Page 38: ...38 PARTS LIST 6709534 MAIN BASE ASSEMBLY ...

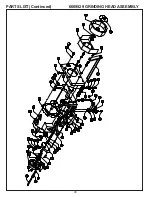

Page 40: ...40 PARTS LIST Continued 6609529 GRINDING HEAD ASSEMBLY ...

Page 42: ...42 PARTS LIST Continued 6709531 TRAVERSE CARRIAGE ASSEMBLY ...

Page 44: ...44 PARTS LIST Continued 6709533 BEDKNIFE SUPPORT ASSEMBLY ...

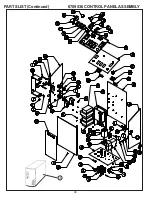

Page 46: ...46 PARTS LIST Continued 6709536 CONTROL PANEL ASSEMBLY 50 ...

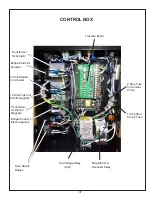

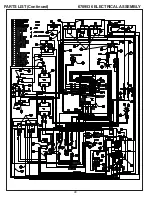

Page 48: ...48 PARTS LIST Continued 6709536 ELECTRICAL ASSEMBLY ...

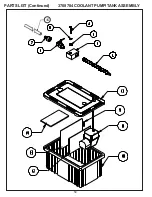

Page 50: ...50 PARTS LIST Continued 3708784 COOLANT PUMP TANKASSEMBLY 15 ...

Page 52: ...52 ...